TM 5-6115-400-12

d. Check for Inoperative Fuel Injection Nozzles.

Run engine at 60 cycles and "cut out" each fuel injection

nozzle in turn by loosening the fuel injection line nut

attaching the line to the fuel injection pump.

Caution:

Keep hands away from loosened

nuts while performing this test.

A decrease in engine speed with injection line

nut loosened indicates that the fuel injection nozzle for

that cylinder is functioning properly. If engine speed

does not decrease, the nozzle is defective and must be

removed, tested, adjusted, and cleaned.

e. Check for Inoperative Fuel Injection Pump.

(1) Do not replace the fuel injection pump

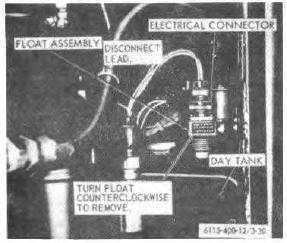

Figure 3-30. Day tank float, removal and

before having a compression test made.

installation.

(2) The compression test will indicate whether

indicates a pressure below specified

or not burned or stuck valves, worn or

minimum and little or no fuel is

scored pistons and sleeves, worn or stuck

observed from disconnected return

rings, etc., are causing the improper

line, an inoperative fuel transfer

engine operation. (Refer to direct and

pump is indicated. The pump must

general support maintenance.)

be removed, inspected, repaired, or

(3) If all causes for insufficient fuel supply

replaced as a unit.

have been eliminated, and the engine still

(d) If a pressure above 30 psi is

runs unevenly and normal engine

indicated by the gage, the fuel

performance is not obtained, the fuel

pressure relief valve is defective

injection pump will be considered at fault

and must be replaced as a unit.

and should be repaired or replaced.

(e) Stop engine and connect fuel return

line to fuel relief valve.

3-39