TM5-6115-593-34

NAVFAC P-8-631-34

TO-35C2-3-463-2

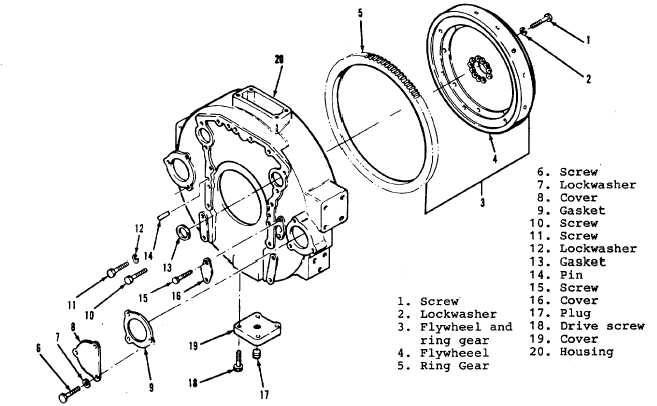

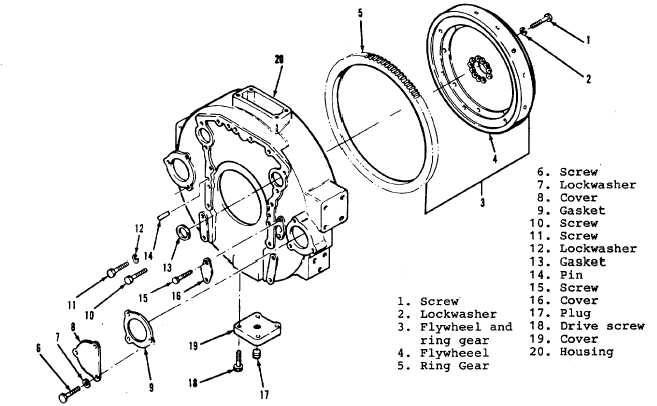

(5) Drive ring gear (5) from flywheel with a

blunt chisel.

(6) Install two 5/8-11 studs in block to guide

flywheel housing during removal.

(7) Drive housing from dowels by tapping on

back side with a soft hammer or wooden

block. Using a suitable hoist, lift housing

from guide studs.

c.

Installation

(1) Install housing on dowels by tapping with a

soft hammer or wooden block.

(2) If an oven with heat control is not available,

heat ring gear (5) with a heating torch from

inside diameter so heat travels outward to

teeth.

(3) Use a Templistick crayon or equivalent to

determine amount of heat applied.

(a) Stroke gear with 600°F (316C) crayon

several times while applying heat.

(4) The crayon will leave a chalk mark until

temperature reaches 600F (316C). At

600F (316C), the crayon will leave a liquid

smear.

CAUTION

Overheating

to

temperatures

above

660°F (349°C) will soften gear.

(5) Place ring gear on flywheel and quickly

drive onto flywheel until gear is firmly

seated.

(6) Index the zero on crankshaft with the zero

on flywheel and assemble flywheel over

studs to crankshaft flange.

(7) Insert lockwashers (2) and screws (1).

Tighten screws alternately, a little at a time,

to pull flywheel up evenly. Continue until all

screws are tight.

(8) Attach indicator gauge to side of flywheel

housing to indicate bore of flywheel. The

total indicator reading must not be greater

than 0.005 inch (0.13 mm).

Figure 13-35A. Ring Gear, Flywheel, and Flywheel Housing

13-71