TM5-6115-593-34

NAVFAC P-8-631-34

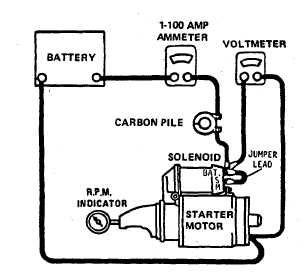

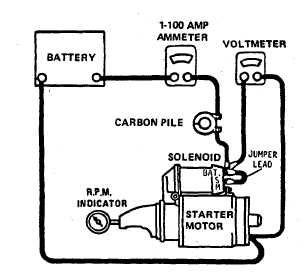

Figure 13-5. No Load Test Circuit (Code A)

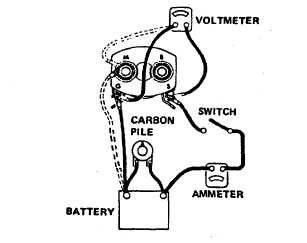

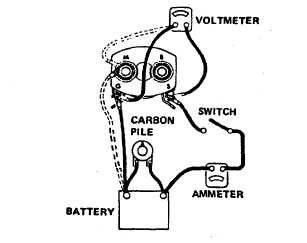

Figure 13-6. Checking Solenoid Hold-In and Pull-In

Windings (Code A)

CAUTION

Do not leave pull-in winding energized for more than

15 seconds.

(3)

To check the pull-in winding, connect the

other battery lead to the M terminal (shown in dotted line).

(4)

Adjust the voltage to 5 volts. Voltmeter

shall read 5V AC and ammeter shall read 10 to 11.5

amps.

TO-35C2-3-463-2

(5)

Replace switch if either winding is

shorted or shows excessive resistance.

j.

Repair. Repair of the starter motor consists of

repairing commutator bars whenever possible (if not

badly burnt) and replacement of parts found defective

during inspection. Repair commutator bars as

follows:

(1)

Using rosin flux, resolder or weld leads in the

riser bars.

(2)

Turn down the commutator in a lathe.

(3)

Undercut and clean the commutator as

indicated in paragraph k.

k. Overhaul. Overhaul of the starter motor consists of

overhauling the armature commutator and

replacement of parts found defective during

inspection. Overhaul the commutator as follows:

(1)

Turn down commutator in an appropriate

lathe.

(2)

Undercut the insulation 1/32 of an

inch wide and 1/32 of an inch deep.

Remove any trace of dirt or copper dust

between slots.

(3)

Sand the commutator lightly with

No. 00 sandpaper to remove any burrs

resulting from the undercutting procedure.

l.

Assembly. Assemble the motor in accordance with

figure 13-4.

(1)

Install the pole shoes (91) and secure with

pole shoe screws (90).

(2)

Install the armature (89) and field coil (99)

in the housing (104).

(3)

Install the lever housing (37) with screws

(26), and washers (27)..

(4)

Position the washer (34) and gasket (33) in

the lever housing and install the drive

assembly (25) in

13-10