TM5-6115-593-34

NAVFAC P-8-631-34

TO-35C2-3-463-2

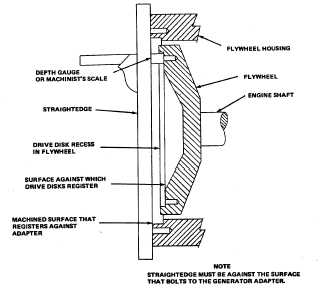

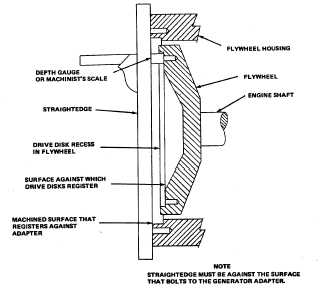

Figure 11-8. Checking Flywheel Housing Runout

CAUTION

Determine that the hoist is of sufficient

strength to adequately support the

weight of the generator. Hoist and

Hoist cables should have a rating of

not less than 6,000 pounds (2,727 kg).

Always make certain extreme care is

taken when moving the generator to

prevent its striking other objects or

personnel. Never apply a lifting force

to structural points other than those

provided for that purpose.

(a)

Install sixteen screws and washers securing

generator assembly (figure 11-5) and six

bolts and locking plate to engine flywheel

housing. Tighten screws.

(b)

Move generator to location on skid base,

line up mounting holes

and install four generator mounting bolts

(figure 11-5) securing generator frame to

the skid base assembly. Do not tighten

bolts at this time.

(c)

Install Control Box Assembly per

paragraph 2-14b.

CAUTION

If fan is moved, make certain that

before generator set is placed in

operation, fan is positioned with

about 1/2 inch (13 mm) clearance

between fan and baffle and all fan

bolts are installed and tightened .

(d)

Tighten mounting bolts to torque shown in

figure 11-5. Make certain generator

mounting pads contact the base evenly and

with equal pressure. Use of shims may be

required.

(e)

After generator is assembled to the engine,

check runout by placing the base of a dial

indicator on a generator frame rib and

positioning the indicator finger on the

generator shaft. Set dial indicator to zero.

Turn generator through at least one

revolution. Total indicator reading should

not exceed 0.005 inch (0.13 mm).

NOTE

Use inspection mirror to read indicator. It

may be necessary to move fan out of the

way. See CAUTION following step (c).

(4)

Installing PMG.

(a)

Install the exciter rotor assembly and the

pilot exciter rotor. Make certain the key is

in place in the shaft before installing exiter

rotor assembly.

CAUTION

Do not apply force to rotating rectifier

or to the armature windings.

11-17