TM 5-6115-584-12

NAVFAC P-8-622-12

TO-35C2-3-456-1

NOTE

Always detach negative (–) cable first

and reattach it last.

b. Battery Top (Hold–down) Frame (see figure

3-23).

(1) Remove. Tag and disconnect battery ca-

bles (10) and jumper cable (11 ) from batteries (1).

Remove six nuts (4) and flatwashers (5) holding top

frame (2) in place, and remove top frame. If hook bolts

(3) do not need replacing, they need not be removed

from frame (6).

(2) Replace. Hook six bolts (3) onto bottom

frame (6). Place top frame (2) over batteries (1) mak-

ing certain hook bolts slide through the top frame.

Secure top frame in place with six flatwashers (5) and

nuts (4). Reattach battery cables (10) and jumper ca-

ble (11).

(3) Repair. Straighten battery top frames

making certain they fit securely over batteries and hold

batteries in place.

c. Storage Batteries.

Battery electrolyte can cause severe

burns to the skin. Always flush ex-

posed parts of the skin with water as

quickly as possible.

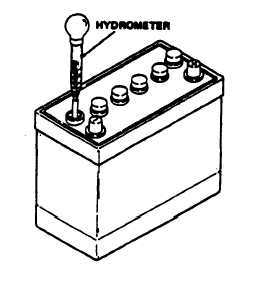

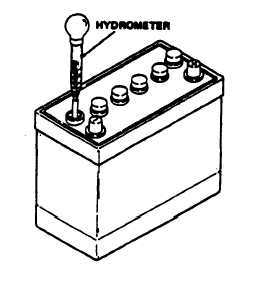

(1) Test. Charge battery for a sufficient time

for battery to be fully charged (1 to 2 hours). Test each

cell of battery separately using a hydrometer. Remove

cap from one cell and draw fluid from that cell into hy-

drometer. Hydrometer must register a specific gravity

of 1.260 to 1.280. If specific gravity is below 1.260,

charge battery. See figure 4–17. Replace fIuid into cell

and replace cap. Check each battery cell using this

procedure. If one or more cells in a battery will not take

a charge, replace battery.

(2) Remove. Remove battery cables and top

frames, a and b above. Remove batteries from battery

frame.

(3) Replace. Place batteries in battery frame

with negative (-) terminals toward control panel end of

generator and positive (+) terminals toward blower

housing end of generator. Install battery top frame and

battery cables as outlined above.

Figure 4–17. Testing Batteries

4-26. ENGINE STARTER ASSEMBLY,

a. Test. On equipment (see figure 4–1 9). On

ASK equipped generators, remove BATTERIES ac-

cess door.

(1) Make sure batteries are fully charged and

that all battery and starter cables are serviceable and

properly installed. Disconnect all starter to solenoid

connection.

(2) Connect voltmeter as shown in figure

4–19, Test a. If voltage is indicated, solenoid is defec-

tive. Proceed to step (4).

(3) Reconnect all starter to solenoid connec-

tions. Connect voltmeter as shown in figure 4–19, Test

a. If battery voltage (24 volts) is not indicated, the

starter (B1 ) may be defective. Proceed to step (4).

(4) Momentarily connect a jumper as shown

in figure 4–19, Test b. Voltmeter reading should drop

to zero and starter should crank engine. If voltmeter

reading does not drop to zero, solenoid is defective. If

voltmeter readings drop to zero but starter fails to crank

engine, starter is defective.

b. Removal (see figure 4-18). On ASK genera-

tors remove batteries access door.

Tag and

disconnect leads (1) thru (6). On Style I Starters, re-

move nut (7), Iockwasher (8), screw (9). Loosen but do

not remove screw (1 0), Iockwasher (11) and swing

4-26

Change 10