TM 5-6115-584-12

NAVFAC P-8-622-12

TO-35C2-3-456-1

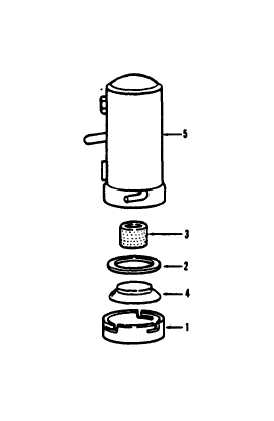

1. Cover

2. Gasket

3. Strainer

4. Magnet

5. Fuel pump

TS

6115-58412/4-13

Figure 4-13. Fuel Pump

(2) Check for continuity between terminals of the

fuel shut-off solenoid. If continuity is not obtained, the

unit is unserviceable.

(3) Check for ground between fuel shut-off solenoid

terminals and ground. If terminals are grounded, the

unit is unserviceable.

(4) Connect the solenoid into test set-up (fig 4-15).

(5) With switch (S1) closed, the plunger should ac-

tuate and the currant draw should be 0.25 ampere dc.

(6) If plunger does not actuate or, if meter reads

above 0.35 ampere, replace solenoid.

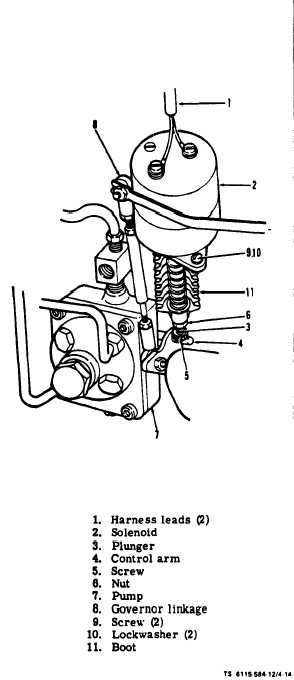

c. Remove (see figure 4-14). Tag and disconnect

harness leads (1). Remove the shut-off solenoid by

removing screws (9) and lockwashers (10).

d. Installation. Mount shut-off solenoid using screws

(9) and lockwashers (10). Reconnect previously tagged

and removed harness wires (1).

e. Adjust. The solenoid plunger (3) should be adjusted so it

fully stops Injection when In the de-energized position. With

engine running at full rated bad, clearance between plunger (3)

and control arm (4) should be at least 1/8 inch. To adjust the

plunger length, turn the knurled head screw (5) and jam nut (6)

on bottom of plunger. On ASK equipped Generator Sets, install

right panel assembly (para. 5-6).

Figure 4-14. Adjusting Fuel Shut-Off Solenoid

Change 7

4-23