REF DES

DESCRIPTION

DS1, DS2

F

S1

INDICATOR LIGHT

FREQUENCY METER, 0-400 Hz

SWITCH

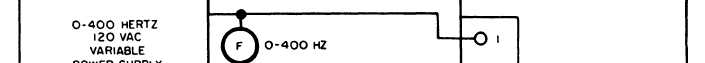

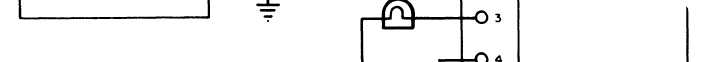

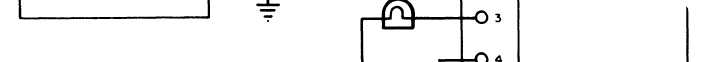

Figure 8-12. Underfrequency Relay Test Set-Up

(c) Check capacitor Cl between points 5 and

6 on terminal board TB106. Capacitance should be 60

uf.

(d) Replace components found to be defective.

(4b) Test the total resistance of rheostat (R28).

Total resistance should be 15,000 ohms + 10%. Test

resistance between wiper arm and either–end of

rheostat. Resistance should vary between 0 and

15,000 Ohms.

(5) Make a point-to-point check of all wiring

and chassis mounted components.

c. Special Relay Assembly.

(1) Check all components for signs of physical

damage.

(2) To test the crank relay (K3), apply 24-28

Vdc across the two small terminals and check for

continuity across the two large terminals.

(3) See figure 8-12 and connect the under-

frequency relay (Kl2) (Mode II Sets) as shown.

Test as follows:

ME 6115-545-34/8-12 C1

(a) Adjust the frequency to 400 Hz and the

input votage to 120 volts. Relay contacts should

“pick up”; lamp DSl should light and DS2 should

extinguish.

(b) Lower frequency slowly until relay con-

tacts drop-out (lights transfer). Contacts should

drop out at 370 + 5 Hz.

(c) Raise frequency slowly until contacts

pick up. DSl should light and DS2 should extinguish.

Contacts should pick up at 370 to 395 Hz.

(d) Raise voltage to 132 volts and check

drop out (lights transfer). Drop out should occur

within ± 1 cycle of drop out at 120 volts.

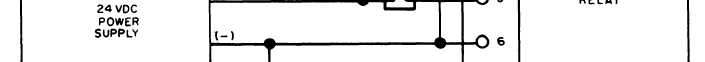

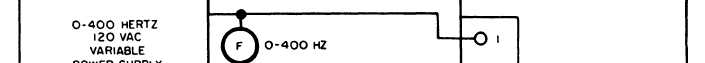

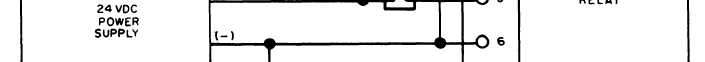

(4) To test the undervoltage relay (Kll),

(Mode XI) connect the relay in a test circuit as illus-

trated in figure 8-13, and proceed as follows:

(a) Adjust ac power supply to 120 volts,

400 Hz. Lamp DSl should extinguish and DS 2

should light.

(b) Reduce voltage slowly to 104 volts and

hold for 2 minutes. Lamp DS1 and DS2 shall main-

tain states.

8-18 Change 1