REF DES

QUANTITY

TEST EQUIPMENT

DESCRIPTION

Rd

1

RESISTOR, FIXED, 5000 OHMS, 1 WATT

Rf, Rg

2

RESISTOR] FIXED, B2 OHM, 10 WATT

Rh, Ri

2

RESISTOR FIXED, 15 OHMS, 5 WATT

Rj

1

RESISTOR, FIXED, 25 OHMS, 5 WATT

M2, M3

2

MILLIAMMETER, DC, 0-1000 MA

M4

1

MILLIAMMETER, DC, ZERO CENTER,

10-0-10 MA

1

SWITCH, ROTARY, 3 POSITION, 1 POLE, 1 AMP

1

DC POWER SOURCE

1

AC POWER SOURCE

1

AUTOTRANSFORMER 2:1 RATIO

ME 6115-545-34/7-5

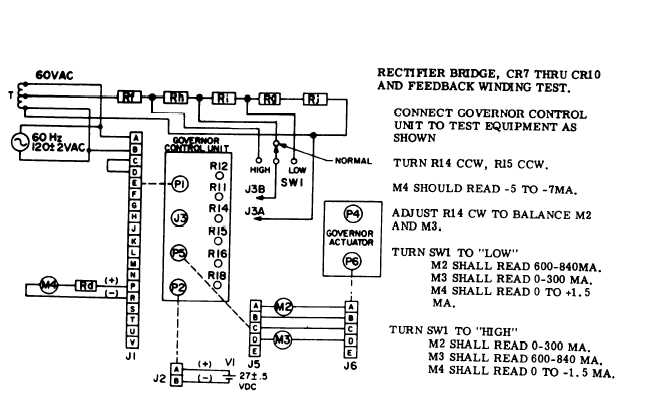

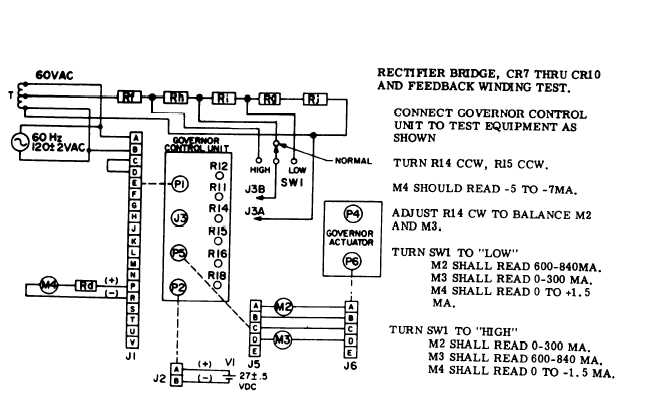

Figure 7-5. Electric Governor Control Unit, Rectifier Bridge and Feedback Winding Test

(50/60 Hz)

(3) Once the set has been stabilized, connect

a 0 - 10 volt range dc voltmeter (high impedance

type -2000 ohms per volt or more) across test

points 3 and 4 with the positive lead at test point 4.

Adjust FREQUENCY ADJUST control to obtain oper-

ating frequency (400 W, or 60 Hz), and then adjust

R14 until volt e across test points 3 and 4 is zero

volts, with no load on generator.

(4) Connect dc voltmeter across tests points 1

and 2 with positive lead at test point 1. Adjust R11

and the frequency adjust control until the dc volt-

meter reads zero volts at nominal frequency. Repeat

the adjustment until the voltage across test points 3

and 4 and across 1 and 2 is zero volts, and the set

frequency is 50 Hz, 60 Hz or 400 Hz with no load

on the engine. If test points 1 and 2 cannot be

zeroed, they must be reduced to a minimum.

(5) Adjust RI 2 until a reading of approximately

4.5 volts is obtained across test points A and B, with

no load on generator.

If this voltage is too low,

response will be sluggish and if it is too high, a rapid

oscillation may occur.

Normal range is 3 to 6 volts.

(6) Adjust R18 clockwise as far as possible,

and R16 counterclockwise as far as possible without

causing oscillation,

NOTE

Increasing the load measurement gain

R15 (turing in a clockwise direction)

will improve transient performance;

therefore it should be adjusted as high

as possible. Transient performance must

be checked using a frequency recorder.

7-8 Change 1