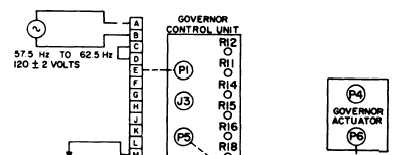

FREQUENCY SENSING CHECK (HIGH AND LOW

REF DES

Ra

Rb, RC

M2., M3

Vl

FREQUENCY)

CONNECT GOVERNOR CONTROL UNIT TO

TEST EQUIPMENT AS SHOWN

TURN Ra SO THE Resistance BETWEEN

P1-M AND Pl-T IS 250 OHMS.

REDUCE THE FREQUENCY OF THE AP-

PLIED 120 ± 2 VOLT SUPPLY UNTIL M2

AND M3 BALANCE.

THE FREQUENCY SHALL BE 57-58 Hz.

TURN Ra SO THE RESISTANCE BETWEEN

P1-M AND P1-N IS 250 OHMS.

INCREASE THE FREQUENCY OF THE AP-

PLIED 120 ± 2 VOLT SUPPLY UNTIL M2

AND M3 BALANCE.

THE FREQUENCY SHALL BE 64-65 Hz.

TEST EQUIPMENT

QUANTITY

DESCRIPTION

1

POTENTIOMETER, 10 TURN, 500 OHM, 5 WATT

2

RESISTOR, FIXED, 250 OHM, 5 WATT

2

MILLIAMMETER, DC, 0-1000 MA

DC POWER SOURCE

AC POWER SOURCE

ME 6115-545-34/7-4 C1

Figure 7-4. Electric Governor Control Unit, Frequency Sensing Check (High and

Low Frequency) (50/60 Hz)

e. Magnetic Amplifier Bias Test (50/60 Hz).

Refer to figure 7-3 and perform the magnetic ampli-

fier bias test.

f. Frequency Sensing Check, High and Low

Frquency (50/60 Hz). Refer to figure 7-4 and

perform the frequency sensing check.

g. Rectifier Bridge, CR7 thru CR30 and Feed-

back Winding Test (50/60 Hz). Refer to figure 7-5

and perform the rectifier bridge and feedback winding

test.

h. Parallel Winding Test (50/60 Hz). Refer to

figure 7-6 and perform the parallel winding test.

i. Resistance Test (400 Hz). Refer to Table 7-3

and perform resistance test.

j. Magnetic Amplifier Bias Test (400 Hz). Refer

to figure 7-7 and perform the magnetic amplifier bias

test.

k. Frequency Sensing Check, High and Low

Frequency (400 Hz). Refer to figure 7-8 and per-

form the frequency sensing check.

L Rectifier Bridge, CR7 thru CRl0 and Feed-

back Winding Test (400 Hz). Refer to figure 7-9

7-6 Change 1

and perform the rectifier bridge and feedback

winding test.

m. Parallel Winding Test (400 Hz). Refer to

figure 7-10 and perform the parallel winding test.

n. Replace any component found to be defective

during tests.

o. For wiring harness repairs, refer to Operator

and organizational Maintenance Manual.

p. If wiring harness has sustained extensive

damage, refer to Chapter 5 for wiring harness

rebuilding procedures.

7-7. Assembly.

a. See figure 7-12 and assemble printed circuit

board. If any connections are opened or bared for

test purposes, or if any defective components are

replaced, the effected area and components must be

coated with polyurethane resin to prevent oxidation

or other corrosion .

The coating must be of a min-

imum thickness of 0.007 inches and air bubble entry

into the applied polyurethane must be controlled so

that the legibility of component coding and identifi-

cation is not impaired. The polyurethane resin to

be utilized will correspond to MIL-I-46058,