TM 5-6115-545-12

TO-35C2-3-444-1

NAVFAC P-8-626-12

TM-00038G-12

3.78 Replacement of Suppression Components, (Cont)

d. Main AC Contactor Three RFI suppression

capacitors C3, C4 and C5 are connected between terminals

A2, B2, and C2 respectively, of the main ac contractor CB2

and ground. Replace suppression capacitors as shown in A

of figure 3–11.

e. Day Tank Solenoid Valve. Diode suppressors

CR27 are provided at the connector of the day tank solenoid

valve. Replace diode suppressors as shown in B of figure

3-11.

3-79. Testing

of Radio Interference Suppression

Components.

Test the capacitors for leaks and shorts using a multimeter or

other capacitor tester. Replace defective capacitors. If test

equipment is not available and interference is indicated,

isolate the cause of interference by the trial and error method

of re- placing each component in turn until the cause of

interference is located and eliminated.

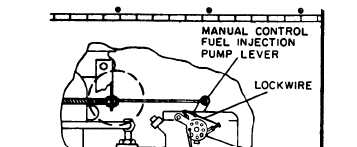

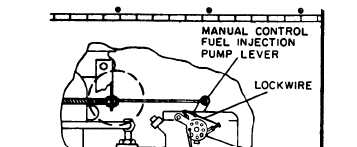

Figure 3-10. Lockwire of Fuel Injector Pump

for Class 2 Operation

Section VIII. ORGANIZATIONAL MAINTENANCE

3-80. General

maintain the engine generator set at the organizational level.

Instructions are provided in sections IX through XLIV for

Where essential, sections are arranged in the most logical

the information and guidance of responsible personnel to

order of disassembly of equipment.

Section IX. BATTERIES, AND RELATED PARTS

3-81. General.

This section contains information on the batteries,

battery tray and slave receptacles of the engine generator set.

Two 12-volt 100 ampere, lead acid type batteries are

mounted side by side on a battery tray. The batteries are

electrically connected in series to supply 24 Vdc for starting

the engine generator set. There is a slave receptacle

electrically connected in parallel with the batteries. The

receptacle facilitates external connection with the batteries,

in order to supply or receive an auxiliary source of electrical

power. A source of 24 Vdc electrical power is therefore

available for other development. Normally, the engine

generator set should be operating so as not to run down the

batteries when supplying this source of dc power.

3-82. Batteries.

a. Replacement. To replace one or both batteries, see

figure 3-4 and proceed as follows:

(1) Remove screw (lA), nut (lB) and clamp (lC).

Disconnect battery negative cable (1) positive cable (2) and

jumper cable (3) from storage batteries (4)

(2) Remove two nuts (5) and lockwashers (6),

which secure battery retainer (7) to studs (8), and remove

storage batteries (4).

(3) Install new storage battery in reverse order of

removal.

b.

Battery Testing.

NOTE

Failure to perform this task prior to

adding distilled water will result in an

erroneous reading.

Battery hydrometer readings should be tested on all

cells monthly. Always test a battery for a degree of charge

before adding water. The specific gravity between the cells

should be within .05. A dangerously low point of charge

indicated by a hydrometer reading of 1.150 or less will

permit the battery to freeze at a temperature of 5° F. A

specific gravity of 1.250 will permit the battery to withstand

temperatures as low as -65°F without freezing. An

acceptable hydrometer reading of 1.210-1.220 at 80°F will

be obtained from a fully charged battery (2.0-2.2 volts dc

per cell).

Battery reading of less than 1.200 or cell variance of .05

or greater will be replaced if attempts to restore the battery

fail. Compare specific gravity readings with previous

readings for cell deterioration.

NOTE

The 6TN and 6TL batteries can be mixed or matched.

However, maintenance–free batteries cannot be mixed or

matched with military batteries. The 6TN and or the 6TL

batteries will perform properly in hot weather as long as

electrolyte levels are carefully monitored. If the electrolyte

expands and causes the level to rise, some fluid must be

removed. If the level becomes too low due to evaporation,

distilled water may be used to obtain the proper level. A

good grade of drinking water (excluding mineral waters)

may be used if distilled water is not available.

Electrolyte (NSNs 6810-00-249-9354 and

6810-00-843-1640) have a specific gravity of 1.280 and

should be used in these batteries. Do NOT adjust the

electrolyte in wet batteries to a lower specific gravity.

Change 17

3-29