S e c t i o n

V I .

F I E L D

E X P E D I E N T

R E P A I R S

T r o u b l e

3 - 6 6 .

G e n e r a l .

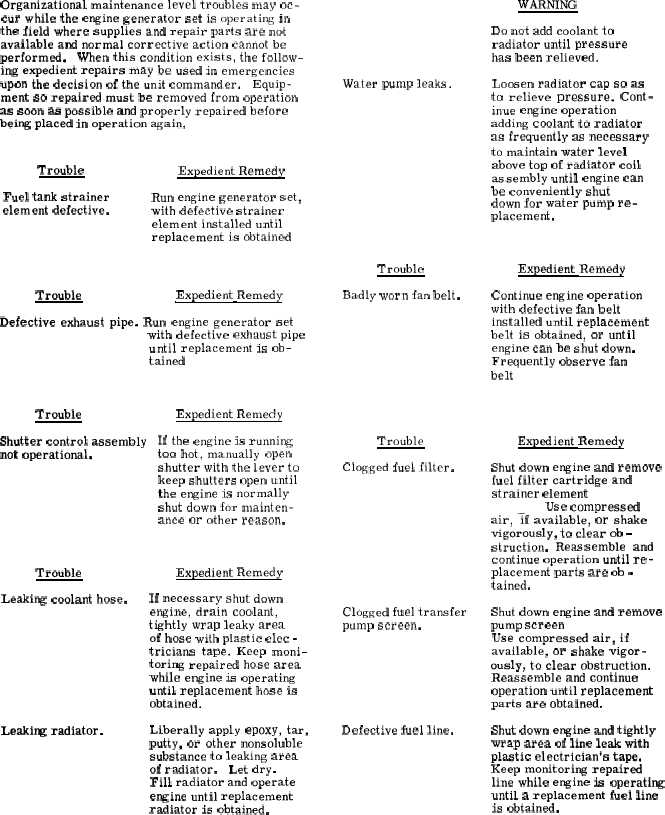

Organizational maintenance level troubles may oc-

cur while the engine generator set is operating in

the field where supplies and repair parts are not

available and normal corrective action cannot be

performed.

When this condition exists, the follow-

ing expedient repairs may be used in emergencies

upon the decision of the unit commander.

Equip-

ment so repaired must be removed from operation

as soon as possible and properly repaired before

being placed in operation again.

3 - 6 7 . F u e l i s n o t S t r a i n e d .

Trouble

Expedient Remedy

Fuel tank strainer

Run engine generator set,

element defective.

with defective strainer

element installed until

replacement is obtained

( p a r a 3 - 3 4 ) .

3 - 6 8 .

H o u s i n g

F i l l e d

W i t h

S m o k e .

Trouble

Expedient Remedy

Defective exhaust pipe. Run engine generator set

with defective exhaust pipe

until replacement is ob-

tained ( p a r a 3 - 8 6 ) .

3 - 6 9 .

E n g i n e

O v e r h e a t i n g .

Trouble

Shutter control assembly

not operational.

3 - 7 0 . L o s s o f C o o l a n t .

Trouble

Leaking coolant hose.

Leaking radiator.

Expedient Remedy

If the engine is running

too hot, manually open

shutter with the lever to

keep shutters open until

the engine is normally

shut down for n>ainten-

ance or other reason.

Expedient Remedy

If necessary shut down

engine, drain coolant,

tightly wrap leaky area

of hose with plastic elec -

tricians tape. Keep moni-

toring repaired hose area

while engine is operating

until replacement hose is

obtained.

Liberally apply epoxy, tar,

putty, or other nonsoluble

substance to leaking area

of radiator.

Let dry.

Fill radiator and operate

engine until replacement

radiator is obtained.

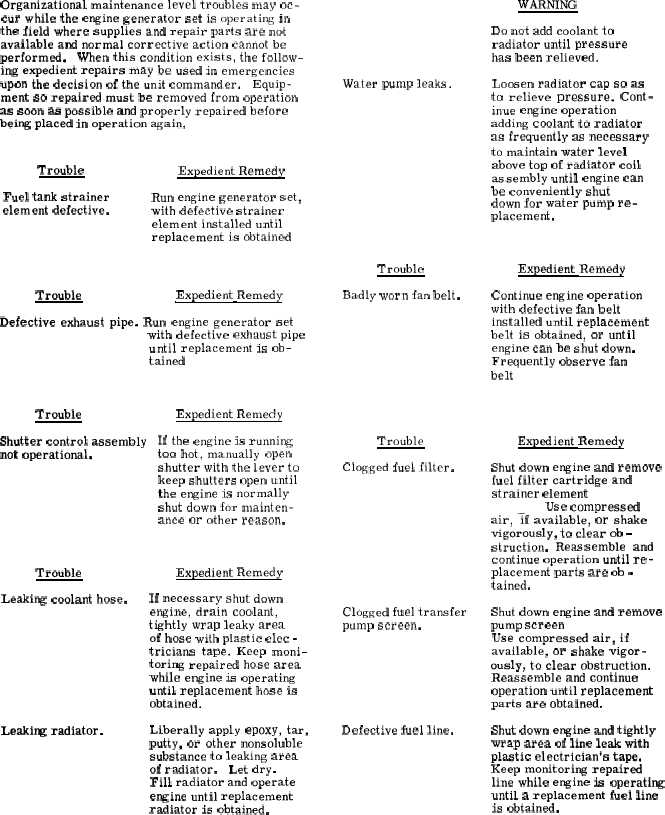

Do

E x p e d i e n t

R e m e d y

WARNING

not add coolant to

radiator until pressure

has been relieved.

Water pump leaks.

Loosen radiator cap so as

to relieve pressure. Cont-

inue engine operation

adding coolant to radiator

as frequently as necessary

to maintain water level

above top of radiator coil

assembly until engine can

be conveniently shut

down for water pump re-

placement.

3 - 7 1 . E n g i n e H e a t U p .

Trouble

Expedient Remedy

Badly worn fan belt.

Continue engine operation

with defective fan belt

installed until replacement

belt is obtained, or until

engine can be shut down.

Frequently observe fan

belt ( P a r a 3 - 1 8 3 . )

3 - 7 2 . E n g i n e C r a n k s B u t W i l l N o t S t a r t o r S t a r t s

a n d

R u n s

E r r a t i c a l l y

o r

M i s f i r e s .

Trouble

Clogged fuel filter.

Clogged fuel transfer

pump screen.

Defective fuel line.

Expedient Remedy

Shut down engine and remove

fuel filter cartridge and

strainer element ( p a r a

3 - 3 4 b ) . Use compressed

air, If available, or shake

vigorously, to clear ob -

struction.

Reassemble

and

continue operation until re-

placement parts are ob -

tained.

Shut down engine and remove

pump screen ( p a r a 3 - 1 6 5 ) .

Use compressed air, if

available, or shake vigor-

OUSIY, to clear obstruction.

Reassemble and continue

operation until replacement

parts are obtained.

Shut down engine and tightly

wrap area of line leak with

plastic electrician’s tape.

Keep monitoring repaired

line while engine is

until a replacement

is obtained.

operating

fuel line

3 - 2 7