TM 5-6115-465-34

TO 35C2-3446-2

NAVFAC P-8-625-34

TM 06858 B/068 S9D-34

CHAPTER 4

GENERATOR SET CONTROLS AND INTERCONNECTING WIRING HARNESS REPAIR INSTRUCTIONS

GENERATOR SET CONTROLS

Section I.

NOTE

GENERAL.

4-1.

Test frequency meter must have an accu-

This section contains maintenance instructions

racy of 0.05 percent.

for the generator set controls. The control cubicle

assembly and sensing monitors contain the controls,

(3) Activate sinusoidal source and adjust

instruments and indicators for controlling and mon-

its output as indicated by the test frequency meter

itoring the operation of the generator set. Pre-

to the lowest frequency-indication on the frequency

cise models of the generator set incorporate a

meter being tested (388 Hz for a 400 Hz frequency

governor control unit which signals the actuator

meter and 48 Hz for a 50/60 Hz frequency meter).

unit to change the fuel injection pump governor

setting which controls engine speed and, thus

(4) Rotate adjusting screw of frequency me-

generator frequency. This function is assumed by

ter being tested until its indication exactly

the manual speed control on utility models. The

matches that of the test frequency meter.

interconnecting wiring harnesses provide electri-

cal connection between major assemblies and the

(5) If the frequency meter being tested can-

control cubicle and fault locating indicator.

not be properly adjusted, replace it and the fre-

quency transducer.

CONTROL CUBICLE ASSEMBLY.

4-2.

(6) When frequency meter being tested has

a. Frequency Meter and Transducer.

been properly adjusted, slowly increase the sinus-

oidal" source-frequency to the highestvalue of the

(1) Refer to the Operator and Organizational

frequency meter being tested (412 Hz for a 400 Hz

Maintenance Manual and remove, clean, and inspect

frequency meter and 62 Hz for a 50/60 Hz fre-

frequency meter and transducer.

quency meter).

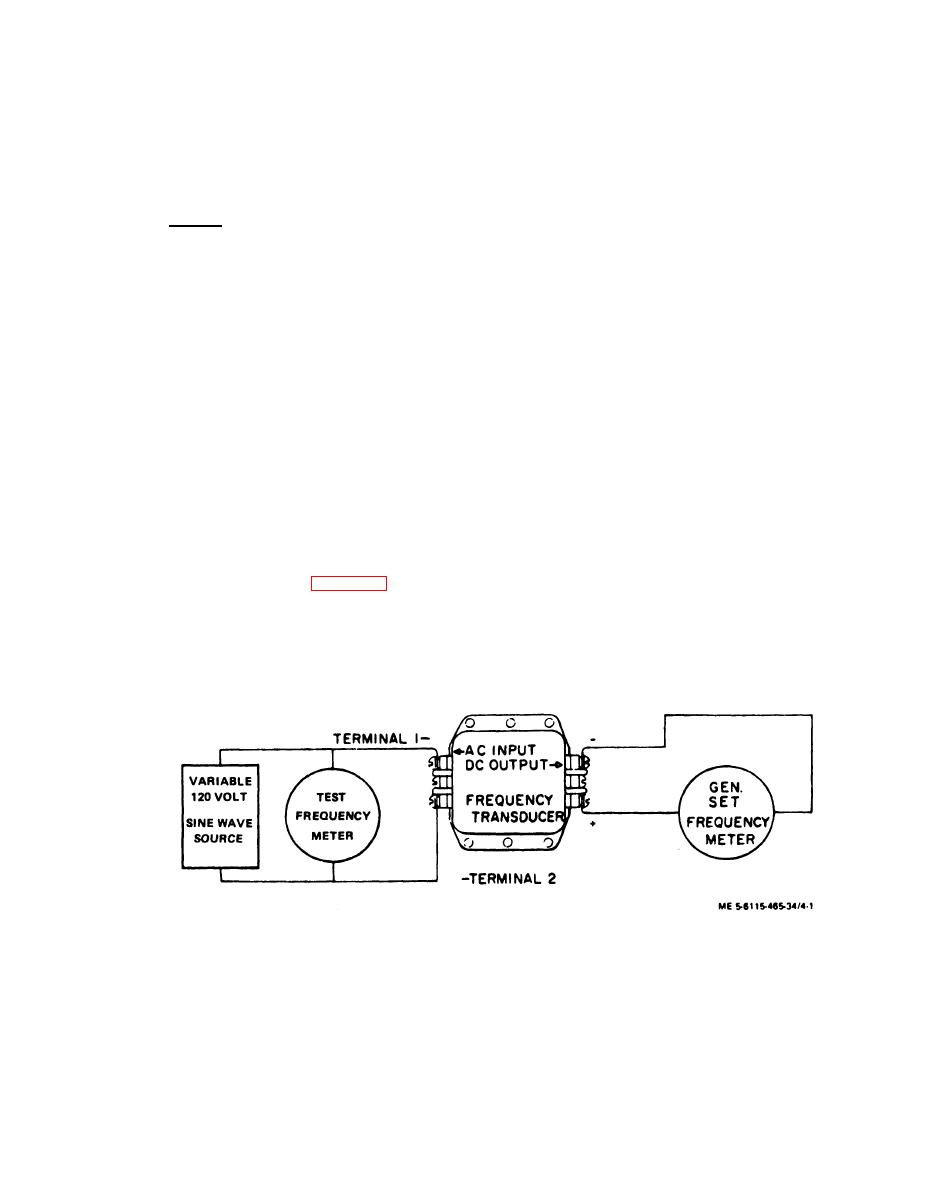

(2) Install frequency meter and transducer

(7) If at any point the indication of the

in a test setup as shown in figure 4-1.

Frequency Meter And Transducer Test Setup

Figure 4-1.

4-1

Change 5