TM 5-6115-465-34

T O 35C2-3464

NAVFAC P-8425-34

TM 06856/06859D-34

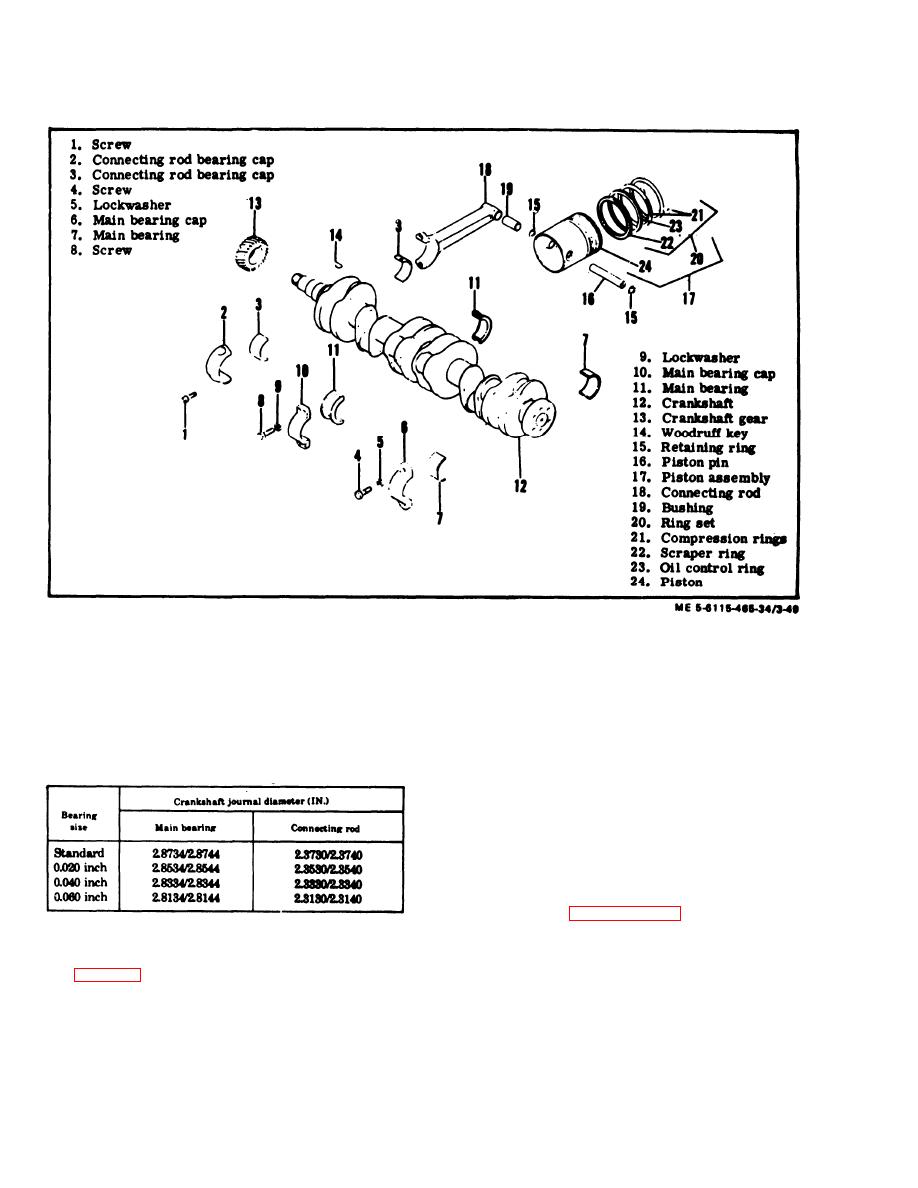

Figure 3-50. Crankshaft, connecting rods and pistons, exploded view.

CAUTION

(9) If replacement of crankshaft gear is neces-

When regrinding crankshaft it is impera-

sary, proceed as follows

(a) Support crankshaft gear in arbor press

tive that the 6/32-inch radius from journal

and press crankshaft and woodruff key from gear.

to cheek be maintained. Crankshaft break-

(b) Heat replacement gear in an oven at 450F.

age may result from improper grinding of

this fillet

(232.2C) for approximately one hour.

(c) Install woodruff key into crankshaft

Table 3-3 Undersized Bearing Journals

CAUTION

Wear asbestos gloves to avoid serious burns

when handling heated gear.

(d) Remove gear from oven and assemble

onto crankshaft. To insure proper

timing of camshaft gear to crankshaft

gear, refer to figure 3-43.

( 7 ) If necessary, regrind crankshaft bearing

(e) Using a driver with an inside diameter of 2

journals to accept undersized bearings in accordance

inches, quickly drive gear into position.

with table 3-3.

(f) Allow crankshaft and gear to COOL

( 8 ) Inspect crankshaft gear for cracks and

(10) Inspect connecting rod for cracks, breaks

chipped, broken or excessive worn teeth.

and excessively worn or damaged bushing.

(11) Check piston pin for nicks, burns, cracks, and

excessive wear.

Change 6

3-76