TO

35C2-3-442-2

P-8-627-34

TM 5-6115-457-34

TM-07464A-35

Section XIII. HYDRAULIC PUMP (PRECISE SETS ONLY)

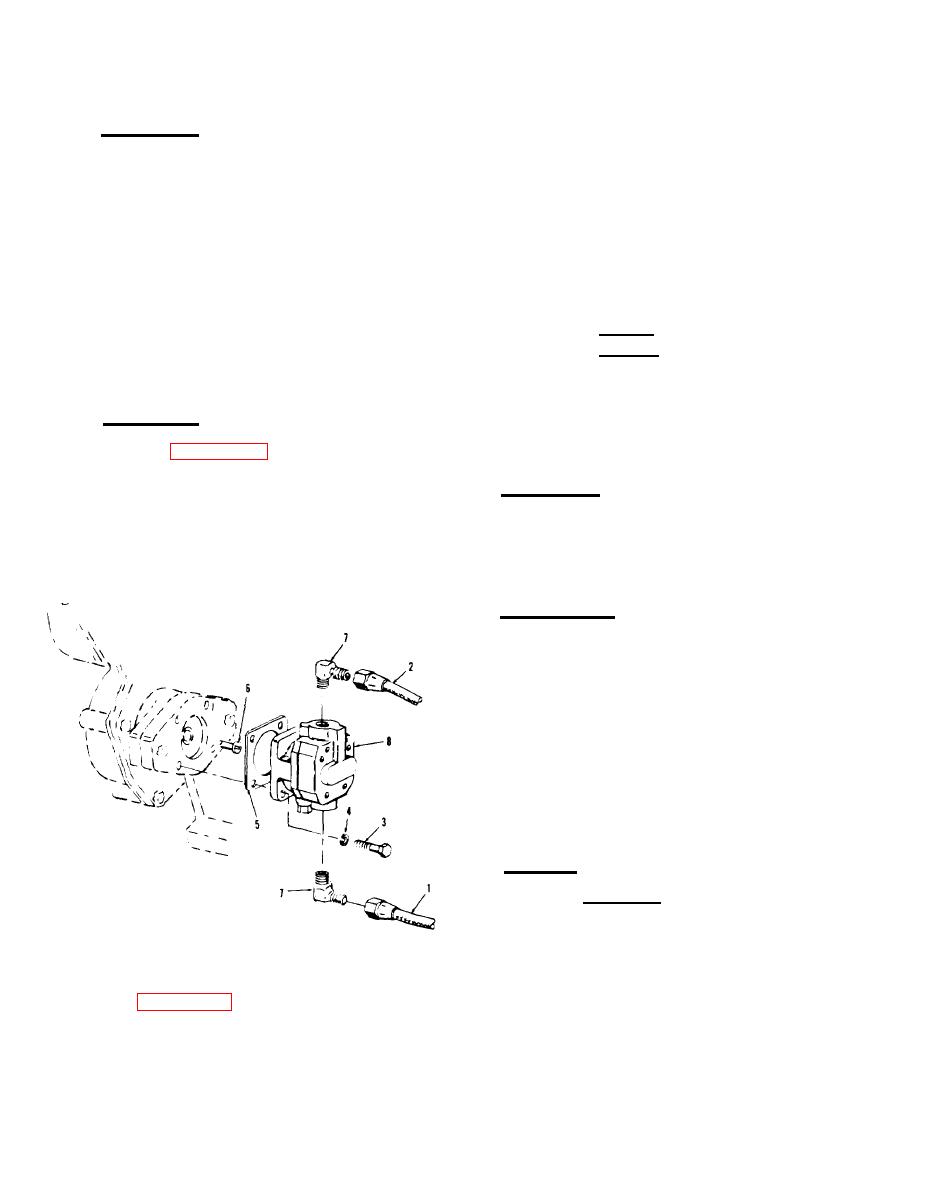

3.

Bolt (4)

GENERAL.

8-93.

4.

Washer (4)

5.

Gasket

The hydraulic pump is mounted to

6.

Coupling shaft

the hydraulic pump drive group and is

7.

Fitting (2)

driven through the camshaft gear. The

8.

Pump assembly

hydraulic pump is used on precise genera-

tor sets only. The hydraulic pump is a

b. When removing pump assembly (8)

positive displacement gear type pump with

from pump drive, hold hand under adapter

a built in adjustable relief valve. The pump

flange on pump drive to catch coupling

is coupled to the pump drive group by means

shaft (6) when it drops out.

of a tang type drive coupling. The pump

I

WARNING

consists of a shaft, dual gears, sleeve

bearing and seal.

Cleaning Solvents are flammable and

moderately toxic to skin, eyes and

8 - 9 4 . REMOVAL.

respiratory tract. Eye and skin

protection required. Good general

Refer to figure 8-23 and remove

ventilation is normally adequate.

hydraulic pump in the order of index numb-

CLEANING.

8-95.

e r s assigned. Pay particular attention to

the following.

Wash pump assembly in an approved

a. Disconnect hose assemblies (1 and 2)

solvent to remove grease, and hydraulic

from pump suction and discharge ports, and

fluid residue. Dry with a lint free cloth.

plug hose assemblies to prevent fluid spil-

lage.

8-96. INSPECTION.

a. Check pump shaft for freedom of

rotation.

b. Inspect coupling shaft (6) for nicks

and burrs on tang end.

c. Inspect condition of threaded holes

in suction and discharge ports.

d. Discard gasket.

REPAIR.

8-97.

CAUTION

Do not use a grinding wheel on

coupling shaft tang.

Figure 8-23. Hydraulic pump, exploded

view (precise sets only)

a. Remove nicks and burrs on drive

Legend to figure 8-23:

tang of coupling shaft using a suitable

1. Hose assembly (suction)

file.

2. Hose assembly (discharge)

8-48

Change 8