P-9-TM-457-35

T.O. 35C2-3-442-2

TM-07464A-35

TM 5-6115-457-34

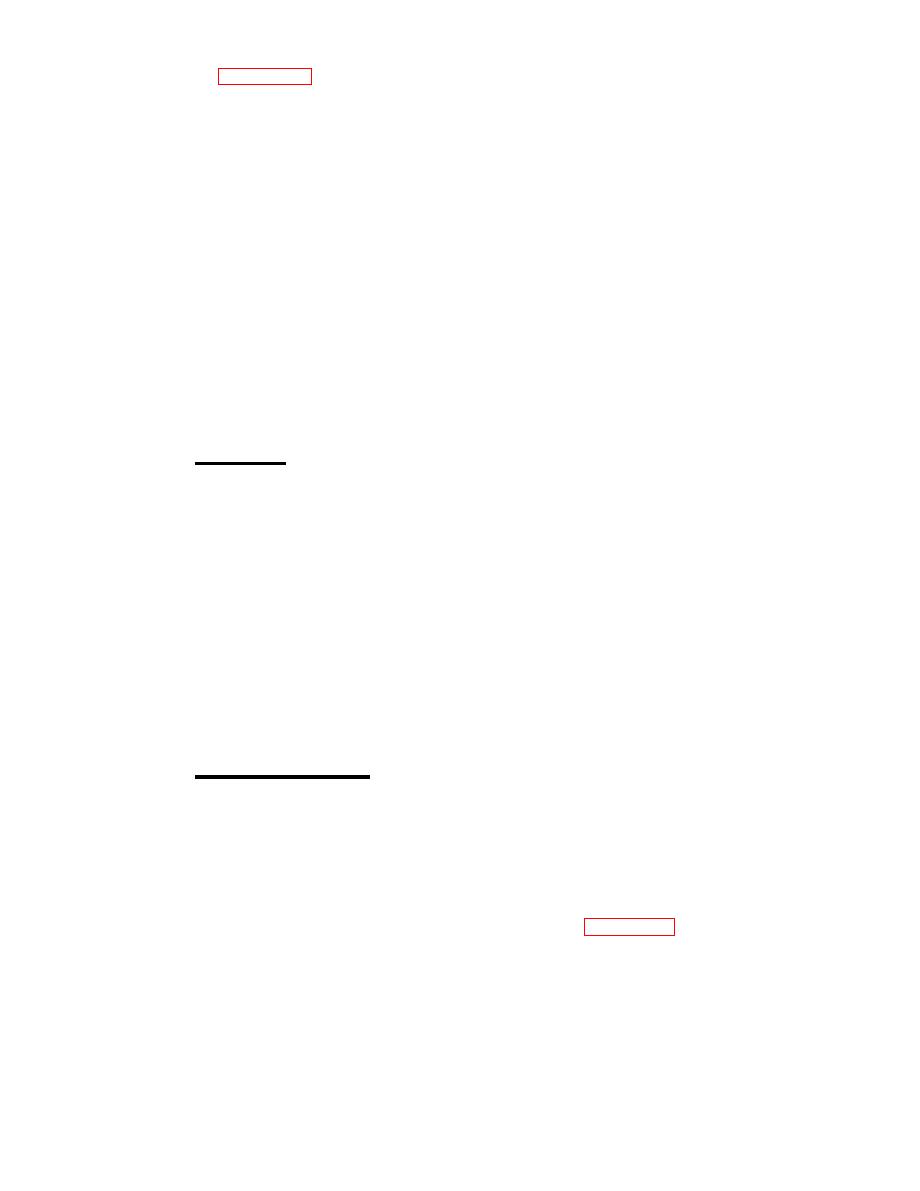

Legend to figure 8-24:

13.

Bolt (3)

Lock washer (3)

1.

14.

2.

Adapter

Nut (3)

15.

3.

Lock washer (3)

Gasket

Bolt

4.

16.

Seal

Nut

5.

17.

Nut

Lock washer

18.

6.

Locknut

7.

Gasket

19.

Ring

8.

20.

Bolt (4)

Bearing

9.

21.

Lock washer (4)

Gear

10.

22.

Cover

Bearing

11.

Gasket

23.

Shaft

12.

Bolt (2)

24.

Adapter

Section XV. GOVERNOR ACTUATOR UNIT (PRECISE SET ONLY)

1. Check for 4 to 6 VDC at test

8-108. GENERAL.

points AB and CD of electric governor con-

The governor actuator unit is located

trol unit (A and D are positive), with engine

on the right side of engine, mounted on top

operating. If voltage at either point is

of the utility governor. The actuating unit

approximately 15 volts, the malfunction is

is an electro-hydraulic servo motor that

a result of an open in an actuator valve

receives intelligence from the electric con-

coil, or connecting circuit.

trol unit and converts this low level elec-

trical information to proportional high level

2. Check that the throttle linkage is

hydraulic pressures that position the engine

not badly worn or disconnected. A worn

throttle by the action of a piston and a float-

linkage can cause sluggish response or

ing lever pivot linkage system. The gover-

drifting frequency. A disconnected or

nor actuator unit is composed of control

broken linkage can cause overspeed, shut-

valves, a piston, a linkage assembly and

down, or no response. Also check linkage

core and armature assembly,

for binding due to dirt or distortion.

3. Check condition of hydraulic

8-109. TEST AND REMOVAL.

filter and the level of hydraulic oil. Either

a. Symptom and Isolation of malfunction.

a clogged or dirty filter or low oil level

A malfunction of the hydraulic throttle actu-

can reduce the hydraulic pressure required

ator is usually indicated by engine shutdown

to operate the actuator.

or overspeed when the Start-Run-Stop

switch is transferred from the START to

4. Check pressure output of hydrau-

the RUN position, frequency drift observed

lic actuator by removing plugs in ports Al

on the frequency meters, sluggish response

and A2 (figure 8-25) and inserting 0 to 400

to load changes, or no response in load

PSI range gauges. The pressure at each

changes. To isolate the malfunction, pro-

port should be 160 25 PSI and equal, with

ceed as follows:

engine operating under governor control.

8-53