T O 35C2-3-442-2

P-8-627-34

TM 5-6115-457-34

TM-07464A-35

b. Repair printed circuits by soldering

a jumper wire across defective area.

Replace all defective components.

c.

d. Solder replacement components

using solder conforming to Federal Speci-

fication QQ-S-571 Sn 60.

6-21. REASSEMBLY.

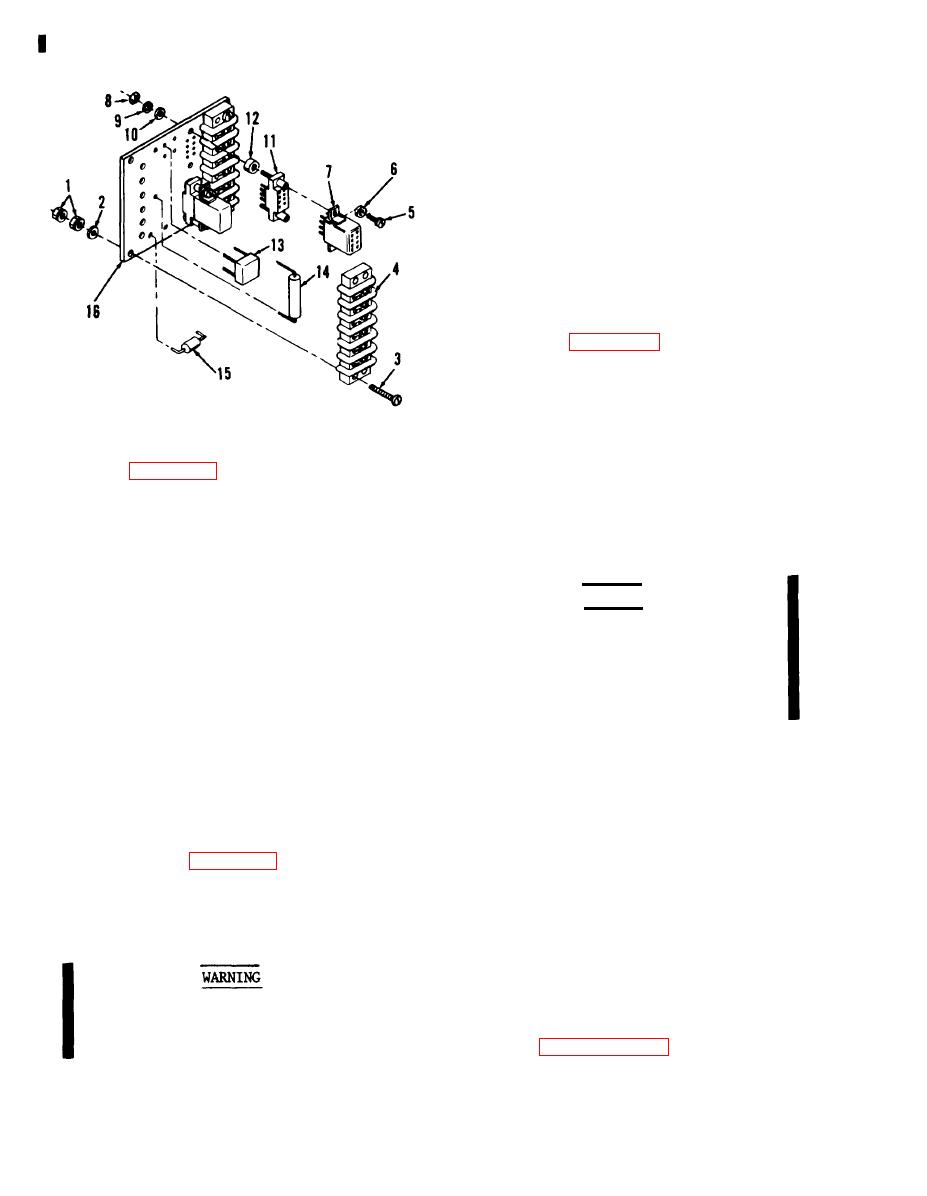

Refer to figure 6-4 and reassemble

control box relay assembly in reverse

order of index numbers assigned. Pay

particular attention to the following.

Figure 6-4. Control box relay assem-

a. When replacing soldered compon-

bly, exploded view

ents, use a suitable heat sink. Solder

Legend to figure 6-4:

joints and/or component leads shall not

10. Lock washer (4)

1. Nut (8)

project more than 0.094 inch beyond the

11. Relay socket (2)

2. Washer (4)

surface of the board.

1 2 . Spacer

3. Screw (4)

1 3 . Silicone bridge

4 . Terminal

rectifier

board (2)

14. F i x e d resistor

5. Screw (4)

WARNING

15. Capacitor

6. Washer (4)

1 6 . Terminal board

Insulating Compound, MIL-I-46058 is

7. Relay (2)

flamable and slightly toxic to eyes,

8. Nut (4)

skin and respiratory tract. Eye and

9. Washer (4)

skin protection required. Good gen-

c. Check resistor for proper ohmic

eral ventilation is normally adequate.

value. (15 K Ohms.)

d. Check capacitor for proper capaci-

b. Spray or brush a conformal coating,

tance value.

0.005 inch thick, of a transparent dielec-

e. Inspect relay sockets for cracked

tric compound corresponding to Specifica-

insulation and broken pin receptacles.

tion MIL-I-46058, Grade S, Type PUR to

f. Test plug in relays for actuation

the assembly.

as illustrated in figure 6-5.

NOTE

6 - 2 0 . REPAIR.

a . Restencil illegible reference desig-

The compound shall securely anchor

nations.

the components to the terminal

board. Terminals for connection to

external circuits shall not be coated.

Avoid breathing fumes generated by

c. Test control box relay assembly as

unsoldering/soldering. Eye pro-

outlined in paragraph 6-16.

tection is required.

Change 8

6-8