P-9-TM-457-35

T.O. 35C2-3-442-2

TM-07464A-35

TM 5-6115-457-34

free cloth, moistened with unapproved

cleaning solvent and dry thoroughly.

6-11. INSPECTION. Inspect the frequency

meter and transducer cases for cracks or

tears and the electrical connectors for bent

pins and insulation breakdown.

6-12.

TEST.

NOTE

The frequency meter and transducer

are a matched set and must be tested

as a set.

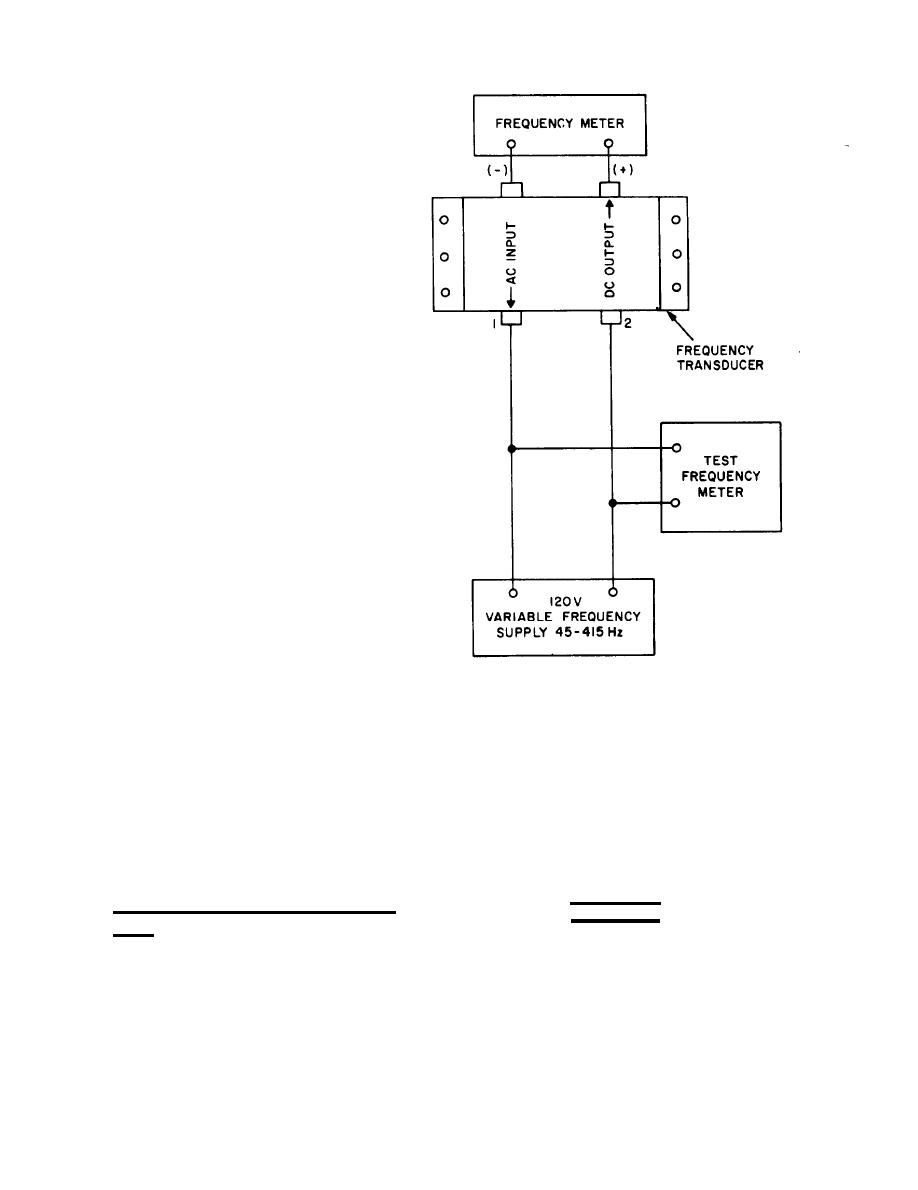

a. Connect a variable frequency 120

VAC frequency generator to the AC side of

the frequency transducer as shown in figure

6-2.

b. Connect a reference frequency meter

across the input. The master frequency

meter shall have 5 times the accuracy of

the set frequency meter and transducer

(1/20 of 1 percent).

c. Vary the frequency from lowest

scale reading to full scale reading.

d. The error at any point on frequency

Figure 6-2. Frequency meter (M6) &

meter shall not be greater than 1/4 of 1

transducer (A2) test setup

percent.

relay assembly (A4) is usually indicated by

failure of the generator set to run when the

e. Remove test equipment. Replace

start- run-stop switch (S2) is positioned to

defective frequency meter and transducer.

RUN or by inability to control voltage from

a remote location. To isolate the mal-

6-13. INSTALLATION. Refer to Operator

function proceed as follows:

and Organizational Maintenance Manual

and install the frequency meter and trans-

1. Loosen three captive studs and

ducer.

hinge control box door open.

CONTROL BOX RELAY ASSEMBLY

6-14.

WARNING

(A4).

Exercise extreme care not to touch

TEST ON EQUIPMENT.

6-15.

exposed electrical connections when

working inside control cubicle with

a. Symptoms and Isolation of Malfunc-

generator set operating.

tion. A malfunction of the control box

6-4