T O 35C2-3-442-2

P-8-627-34

TM 5-6115-457-34

TM-07464A-35

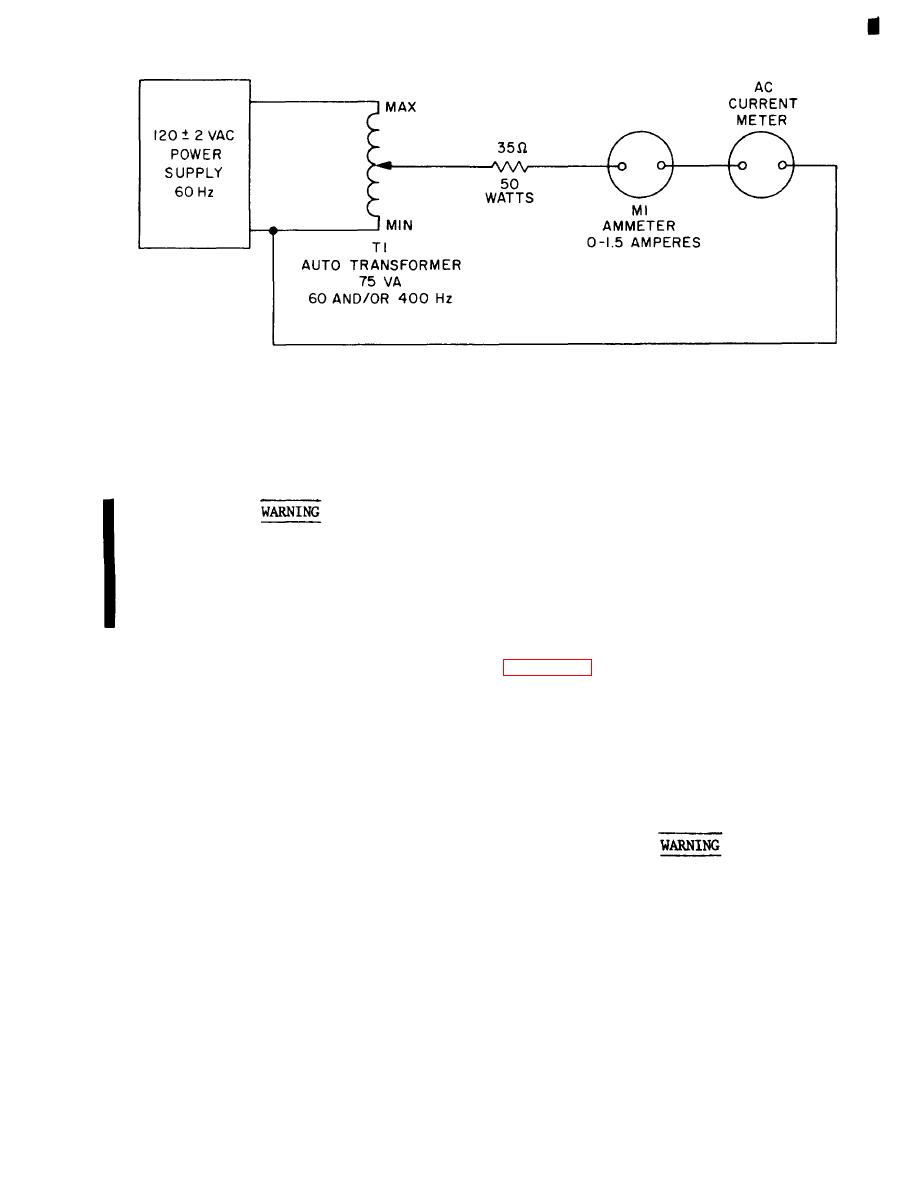

Figure 6-6. AC current meter (M8) test setup

6-32. CLEANING.

e. Check resistor for continuity and

proper ohmic values.

a. Clean electrical components and in-

struments with a clean lint-free cloth

f. Check rheostats for continuity and

moistened in an approved cleaning solvent

for proper adjustable range of resistance.

and dry thoroughly.

g. Inspect terminal lugs for security

and condition.

Cleaning Solvents are flammable and

moderately toxic to skin, eyes and

h. Inspect wiring for defective insula-

respiratory tract. Eye and skin

tion and electrical connectors for damaged

protection required. Good general

threads; bent, loose, or missing pins.

ventilation is normally adequate.

Check each harness wire from connector

b. Clean metal parts in unapproved

pin to wire end for continuity, refer to

cleaning solvent and dry thoroughly.

to case and surrounding pins.

6-33. INSPECTION.

i. Inspect sheet metal parts for bent

NOTE

c o r n e r s , distortion, cracks, tears, and

dents.

Figure l-6 is the schematic for the

6 - 3 4 . REPAIR.

control cubicle.

a. Straighten dents or distorted areas

of the box using proper tools.

a. Inspect meters and gauges for dam-

aged cases and faces.

Welding operations produce heat,

b. Check switches for continuity.

highly toxic fumes, injurious

radiation, metal slag and air-

c. Inspect terminal boards for cracked

borne particles. Welding gog-

gles, with proper tinted lenses,

insulation, stripped threads, and missing

apron or jacket and welder's

jumper strips.

boots are required.

d. Check capacitors for opens and

b. Minor cracks may be repaired by

shorts.

welding.

6-11

Change 8