TM 5-6115-400-35

The ends of the teeth engage with

the pinion of the starter.

(c) Drive ring gear down tight against

shoulder on the flywheel. Allow ring

gear to cool slowly; do not cool with

water.

e. Flywheel Installation.

(1) Install flywheel by reversing the removal

procedure.

(2) After flywheel is assembled to the

crankshaft, tighten the flywheel nuts to the

specified torque of 16 to 170 ft. lbs.

(3) Attach a dial indicator to the flywheel

housing and check flywheel face for

runout (fig. 81).

Note. Insert a suitable bar into the

timing hole and pry flywheel to the rear

to eliminate crankshaft end play so dial

indicator reading is accurate.

(4) Flywheel face run-out should not exceed

.0005 inch maximum total indicator

reading per inch of flywheel diameter.

(5) Readjust indicator so that indicator finger

rides the bore of the flywheel housing (fig.

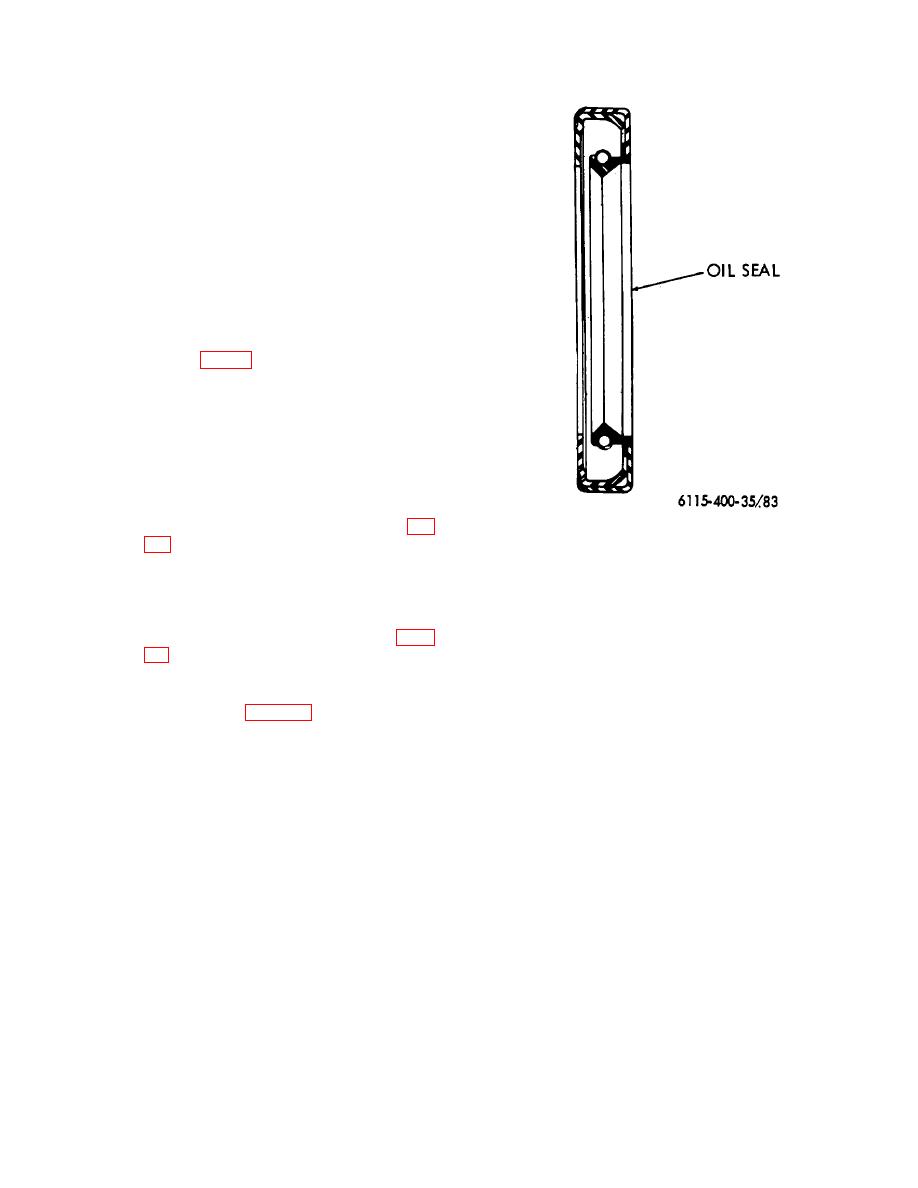

Figure 83. Crankshaft rear oil seal.

.008 inch total indicator reading.

(4) Inspect housing for cracks and other

54. Flywheel Housing

damage; repair or replace housing if

a. Removal.

damaged.

(1) Remove flywheel from the engine (para

c. Crankshaft Rear Oil Seal Installation.

(1) Clean oil seal bore in the flywheel

(2) Remove capscrews securing the oil pan to

housing.

the flywheel housing.

(2) The O.D. of the seal has a layer of red-

(3) Remove bolts (fig. 80) securing flywheel

colored sealant which eliminates the use

housing to the cylinder block.

Tap

of a sealing compound on the O.D. of the

housing with a soft-headed hammer to

seal prior to pressing it into the flywheel

break it loose from the housing dowels;

housing.

remove the housing.

(3) Position seal squarely with bore in

b. Cleaning and Inspection.

housing and, using a seal installer,

(1) Remove

housing-to-block

preformed

carefully drive seal into flywheel housing

packing

and

housing-to-camshaft

until it is seated against the seal stop in

preformed packing.

the bore.

(2) Remove and discard crankshaft rear oil

Note. The seal must be installed with

seal.

sealing lip of seal directed toward the

cylinder block.

(3) Thoroughly clean housing with cleaning

solvent.

(4) Make certain the crankshaft flange on

which the seal rides is free from nicks or

burrs.

Polish with crocus cloth if

necessary.

116