TM 5-6115-400-35

(2) Install lower shaft and gear assembly in

the pump body, inserting splined end of

the shaft through the pump body

bushings.

(3) Install upper shaft and gear assembly in

the pump body, with end of the shaft

containing the keyway facing toward the

cover end.

(4) Install the pump cover and gasket in

position on the pump body and dowel

pins; secure with capscrews and locking

wires.

Note. It is recommended that a new

cover gasket he used.

(5) Install the key in the keyway of the upper

shaft. The interference fit between the

pump driving gear and the upper shaft is

.001 inch-.0025 inch. Heat the pump

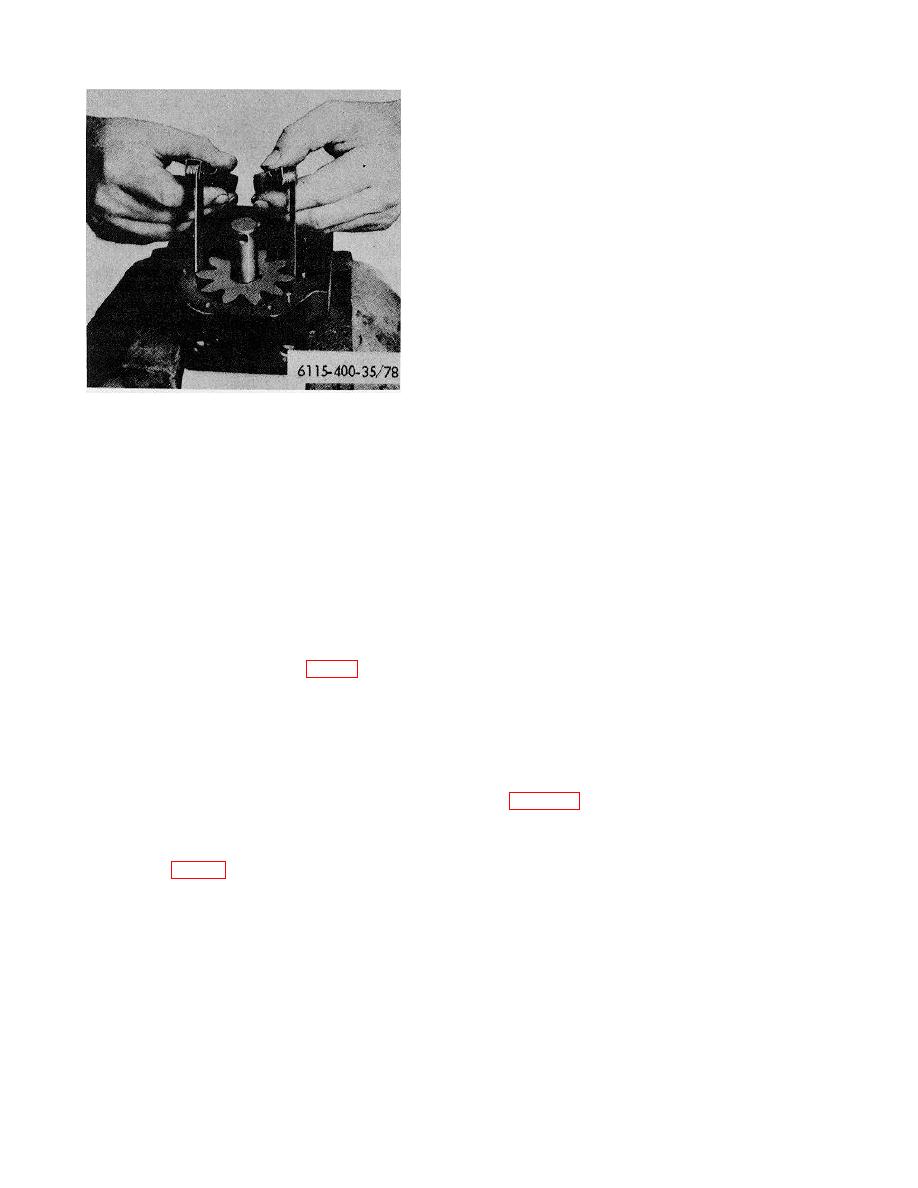

Figure 78. Checking radial clearance between

driving gear in lubricating oil to a

gear teeth and pump body.

temperature of approximately 260 .

F

Coat shaft, at gear location, with a

Three bushings are installed in the pump

mixture of white lead and oil; press gear

body bores; the flanged bushing in the

into position on the shaft.

upper shaft bore and the two plain

Note. When installing the driving

bushings in the lower shaft bore. The

gear onto the shaft, press gear onto

upper shaft bushing must be installed so

shaft only far enough to aline the holes

inner end (gear end) of the inner bushing

for the roll pin.

is 1/32 inch in from the inner machined

(6) The specified clearance between the

face of the body; the outer end of outer

driving gear and front machined face of

bushing should be located 1/32 inch in

the cover is .010 inch-.029 inch. Install

from outer face of the pump body.

the roll pin in position in the driving gear

(12) Remove, disassemble, and inspect the

and shaft. Secure by peening the gear

pressure relief valve (3, fig. 76).

hub over each end of the pin.

The piston must slide smoothly in the bore

e. Installation. All attaching capscrews, used on

of the valve body. When the piston or

the oil pump and associated tubing, are drilled head

bore of the valve body shows excessive

capscrews and MUST be locked with locking wire after

wear or roughness, a new valve assembly

they are installed and tightened to the proper torque.

must be installed.

This will prevent their working loose and causing

(13) Clean valve parts, reassemble, and

possible serious damage to the engine.

reinstall the valve in the pump discharge

See figure 76.

tube.

(1) Position the oil pump under the front main

(14) Remove and clean the oil screen and

bearing cap and turn the pump driving

reinstall in the oil screen cover.

gear until it meshes with the crankshaft

d. Assembly (fig. 77).

gear. This will allow the hollow dowels,

located in the pressure pump body, to

(1) Lubricate the bushings and shaft and gear

position

assemblies with clean engine oil.

112