TM 5-6115-400-35

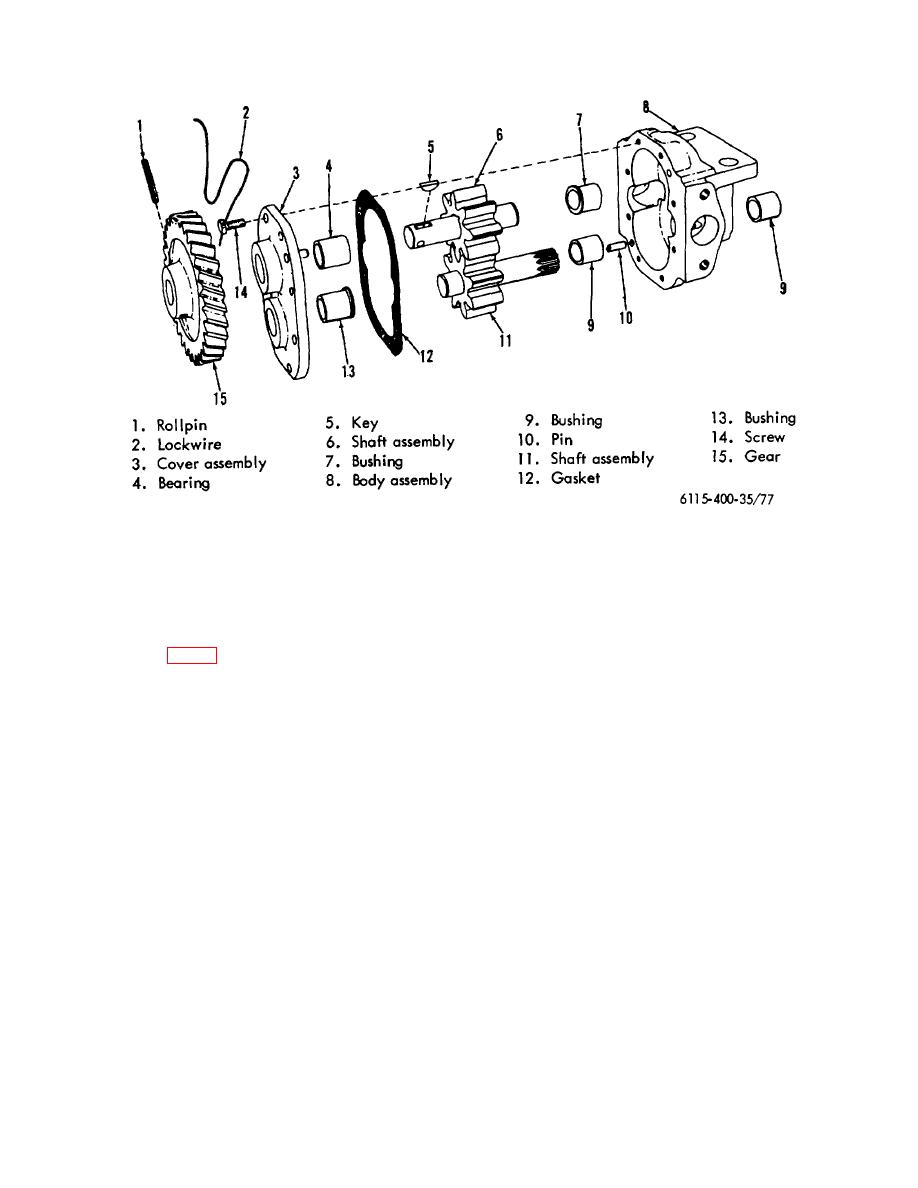

Figure 77. Oil pump-exploded view.

(c) Subtract the gear thickness from the

When the radial clearance exceeds .005

depth micrometer reading.

The

inch it will be necessary to replace worn

difference is the end clearance of

parts.

the gears.

(7) Remove upper shaft and gear assembly

(10) Inspect the pump cover bushings and

(6, fig. 77).

pump body bushings for wear or scoring

(8) Remove any burrs from splined end of the

and replace if necessary. The specified

lower shaft and remove shaft and gear

clearance between upper and lower shafts

assembly from the pump body.

and the bushings is .0015 inch-.003 inch.

(9) The maximum allowable end clearance of

After installing new bushings in the pump

the gears to the pump body is .007 inch.

body and in the pump cover, the bushings

The clearance may be checked as

should be reamed to .7495 inch-.7505

follows:

inch. The specified diameter of the upper

(a) Measure the thickness of the gears

and lower shafts at the bushing locations

with a micrometer. Make note of

is .7475 inch -.7480 inch.

the figure.

(11) Install the plain bushing in the upper shaft

(b) Place a new gasket on the cover

bore and the flanged bushing in the lower

face of the pump body. Place a

shaft bore in the pump cover. The two

depth micrometer in position on the

bushings must be flush with or below the

gasket, and pressing firmly measure

machined inner surface of the pump

the depth of the counterbore at a

cover.

point of gear contact.

111