TM 5-6115-400-35

(2) Tighten the hex nut until the "C" washer

contacts the front machined surface of the

cylinder block.

Note.

This will push out the old bearing

and pull the new bearing into the

correct position.

(3) Use a wire to make certain the oil hole in

bearing is aligned with the oil hole in the

block.

(4) Reassemble the tool as shown in

Operation No. 2 and install the

intermediate bearing.

(5) Reassemble the tool as shown in

Operation No. 3 and install the other

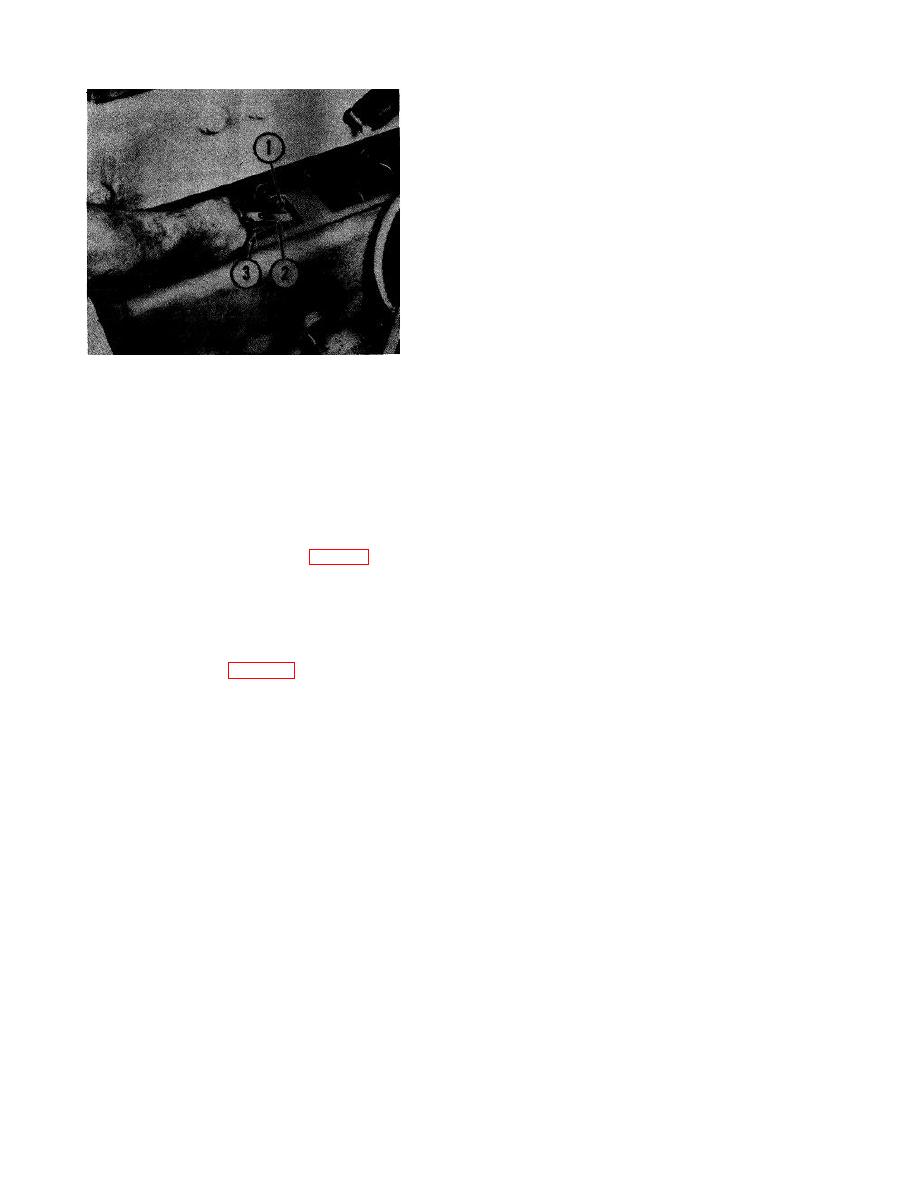

1. Camshaft bearing

intermediate bearing.

2. Feeler gouge

(6) Reverse and reassemble the tool as

3. Camshaft

shown in Operation No. 4 and remove

6115-400-35/88

and install the rear bearing.

Figure 88. Checking camshaft bearing clearance.

(7) Install the camshaft and the rest of the

(5) It is possible to remove and install

components by a direct reversal of the

camshaft bearings without removing the

removal procedure.

oil pan; however, to prevent dirt from

(8) Check the fuel injection pump timing

falling into the oil pan and to facilitate

(refer to TM 5-6115-400-12).

camshaft

bearing

removal

and

57. Pistons and Connecting Rods

installation, it is advisable to drain the oil

a. General.

and remove the oil pan (para 50).

(1) The pistons are cast aluminum alloy,

(6) Refer to figures 89 and 90 and remove

precision

machined,

cam

ground,

bearings.

balanced, and tin plated. Each piston is

c. Bearing Installation.

fitted with three compression rings and

(1) Assemble the camshaft bearing removing

one oil control ring, located above the

and installing tool with a new front bearing

piston pin. Holes are drilled through the

as shown in figure 90.

walls of the piston at the oil ring groove to

Note.

allow excess oil to return to the oil pan.

Four camshaft bearings are used.

The piston pins are full floating and are

Each bearing has an oil groove

held in place in the piston by two retainer

machined

into

the

outer

rings.

circumference, with a 1/8 inch and

(2) The connecting rods are made of drop-

3/8 inch oil hole located 180 apart.

forged, heat-treated steel, rifle-drilled for

Determine and mark the location of

pressure lubrication of the piston pin and

the oil holes in the cylinder block so

are statically and electronically balanced.

that when the new bearings are

(3) The connecting rod bearings are precision

installed, the 3/8 inch hole in the

type, replaceable without machining.

bearing will index with. the oil hole

Each half of the bearing shell is prevented

in the cylinder block. The front and

from radial movement by a tang. An oil

rear bearings are 1-7/8 inch long and

hole in the center of each shell allows oil

the intermediate bearings are 1-3/8

from

inch long. The bearings are of the

precision type and do not require

reaming after installation.

120