TM 5-6115-400-35

piston skirt, piston rings, and ring

(b) Remove the piston rings using a

grooves should be thoroughly

ring remover and installer tool.

inspected. Be sure oil drain holes in

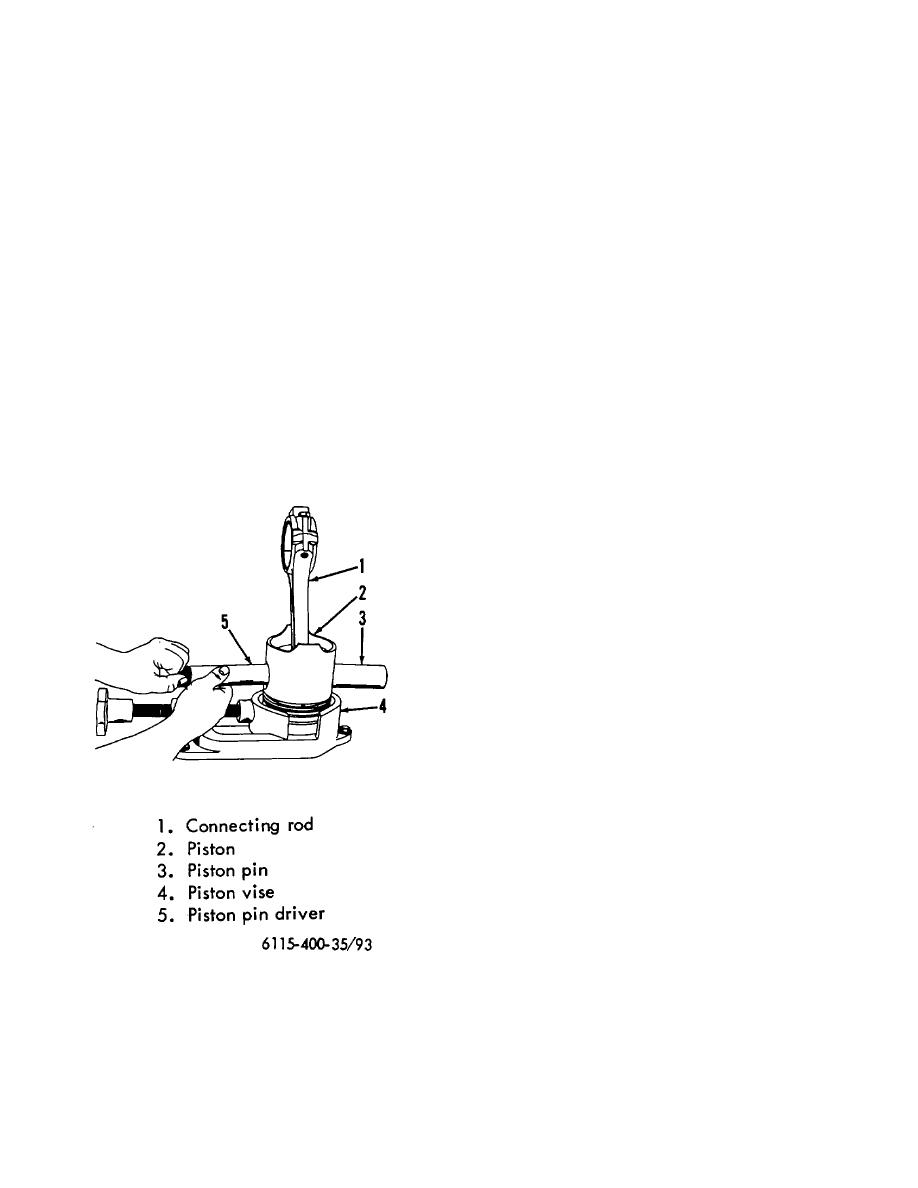

(c) Using a piston pin remover and

the oil ring grooves are open and

installer tool drive the piston pin

clean. If the cleaning solution does

from the piston. The pin should

not remove all carbon from the

drive out easily since the specified

bottom of the ring grooves, break

clearance between a new piston and

the old rings in half and use the butt

pin is .0001 inch to .0005,inch loose

ends as scrapers. Be careful to

at room temperature.

remove only carbon or foreign

(3) Piston and piston pin inspection.

material; do not scrape away any

(a) The normal pattern of wear on

metal from the side or bottom of the

pistons will show maximum wear in

ring grooves.

the compression ring grooves.

Caution.

Seldom is piston replacement

Some types of solvent contain

required because of excessive wear

chemicals injurious to aluminum

in the oil ring grooves or because

alloy.

Do not use this type of

the piston skirt or piston pin bores

cleaning agent.

are excessively worn.

(c) The piston skirt should be carefully

(b) Piston walls and ring grooves may

examined for score marks or other

be cleaned by using a solvent and

indications of improper piston

then

blowing

off

with

dry

clearance. Inspect the inside of

compressed air. After cleaning, the

pistons for cracks; scored or

cracked pistons should be replaced.

Check pistons for wear.

Note.

The skirt diameter of a new piston is

5.243 inch to 5.244 inch (measured at

right angles to piston pin and at the

bottom of the skirt); the inside

diameter of a new cylinder sleeve is

5.251 inch to 5.252 inch, giving a

running clearance from .007 inch to

.009 inch. Any deviation from these

measurements will indicate the

amount of wear on the piston and/or

the cylinder sleeve.

(d) If the piston rings are removed from

the pistons, even after a short

period of operation, do not reinstall

the same rings; in most cases, used

rings will not again seat properly.

The O.D. of new piston rings have

tool marks and reasonably rough

surfaces which allow for a fast wear-

in and seating of the rings to the

cylinder walls. After a period of

operation, the rings wear or lap

themselves to fit perfectly with the

cylinder walls and the rings "seat".

Figure 92. Removing pin from piston.

(e) If the wear in the piston

compression ring grooves does not

124