TM 5-6115-400-35

have replaced them one of the marks must be

deleted. Delete the calibrating mark stamped

on the control sleeve, use a very fine narrow file

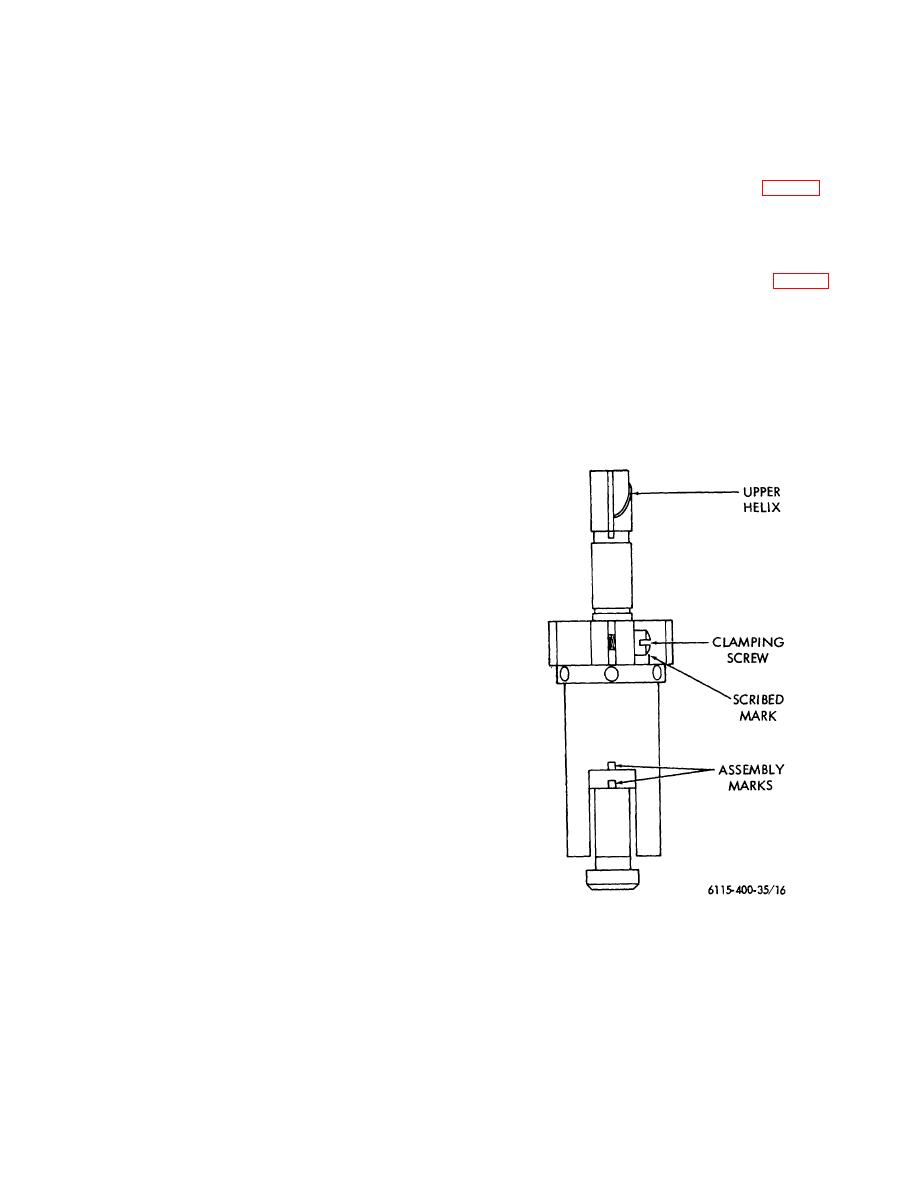

Note. The assembly marks on the yoke

for the operation. (Do not file at the bench

of the plunger and on the guide slot of the

where the pump assembly is being done.) After

control sleeve must coincide (fig. 16). The

the calibrating mark has been removed,

plunger must slide freely in its barrel and

thoroughly clean the control sleeve and dry with

also in the slots of the control sleeve.

dry compressed air. Replace control sleeves

Release the plunger puller and remove it.

meshing the control sleeve segment with the

control rack and positioning the control sleeves

(8) Replace tappet guide screws (44, fig. 15) and

so that the segment clamping screws are

gaskets (45) and tighten to 145-155 inch lbs. To

parallel with the control rack.

facilitate the installation of the camshaft later,

install the tappets without the timing spacer (49).

Caution. Move control rack to maximum

Special Service Tool TSE 76160 or equivalent

travel in both directions to see that the slot

is used to compress the plunger springs. Screw

in gear segment lines up with boss on

the base plug attached to the tool in number one

.pump housing at each end. If it does not,

base hold, position the lever so the brass ram

then gear is not timed properly and will have

will enter the tappet roller.

to set gear segment in proper tooth on

control rack. Check that the control rack

operates freely.

The deleted calibration

mark will be replaced in alinement with the

mark on the gear segment after the pump

has been calibrated.

(6) Replace upper spring seat (55) over control

sleeves and insert the plunger springs (54)

through the base plug bore, so it rests on the

upper spring seat.

Caution. The plunger and barrel are lapped

assemblies and it is imperative that the plunger

returns to its respective barrel.

(7) Hold the correct plunger for the particular barrel

being served in a vertical position with the

special plunger puller, slip the lower spring seat

on the plunger above the plunger yoke. Insert

the plunger into the barrel through the base plug

bore. Exercise care, do not use force when

inserting

the

plunger.

Figure 16. Alining plunger and control sleeve

assembly marks.

42