TM 5-6115-400-35

(10) Adjust the graduated wheel on the test

stand so that the zero mark on its rim

lines up with the pointer.

(11) Recheck the number one pump element

for port closing to make sure that the fuel

stops flowing from the delivery valve

holder when the pointer lines up with the

zero mark on the test stand wheel. THIS

IS IMPORTANT.

(12) Having thus determined the port closing

position for plunger number 1, remove the

delivery valve holder and re-install the

delivery valve and spring previously

removed. Make sure these parts are

clean. Replace the delivery valve holder

and tighten it firmly, but not excessively.

(13) Now proceed to the next pump element in

the firing order which is 1-5-3-6-2-4.

Determine port closing of the next pump

element in the same manner as outlined

for plunger number one, except that it

should occur 60 degrees later. Proceed

until all six pump elements are timed at

60 degree intervals in firing order.

(14) As an example, when checking the

number five plunger, the fuel should stop

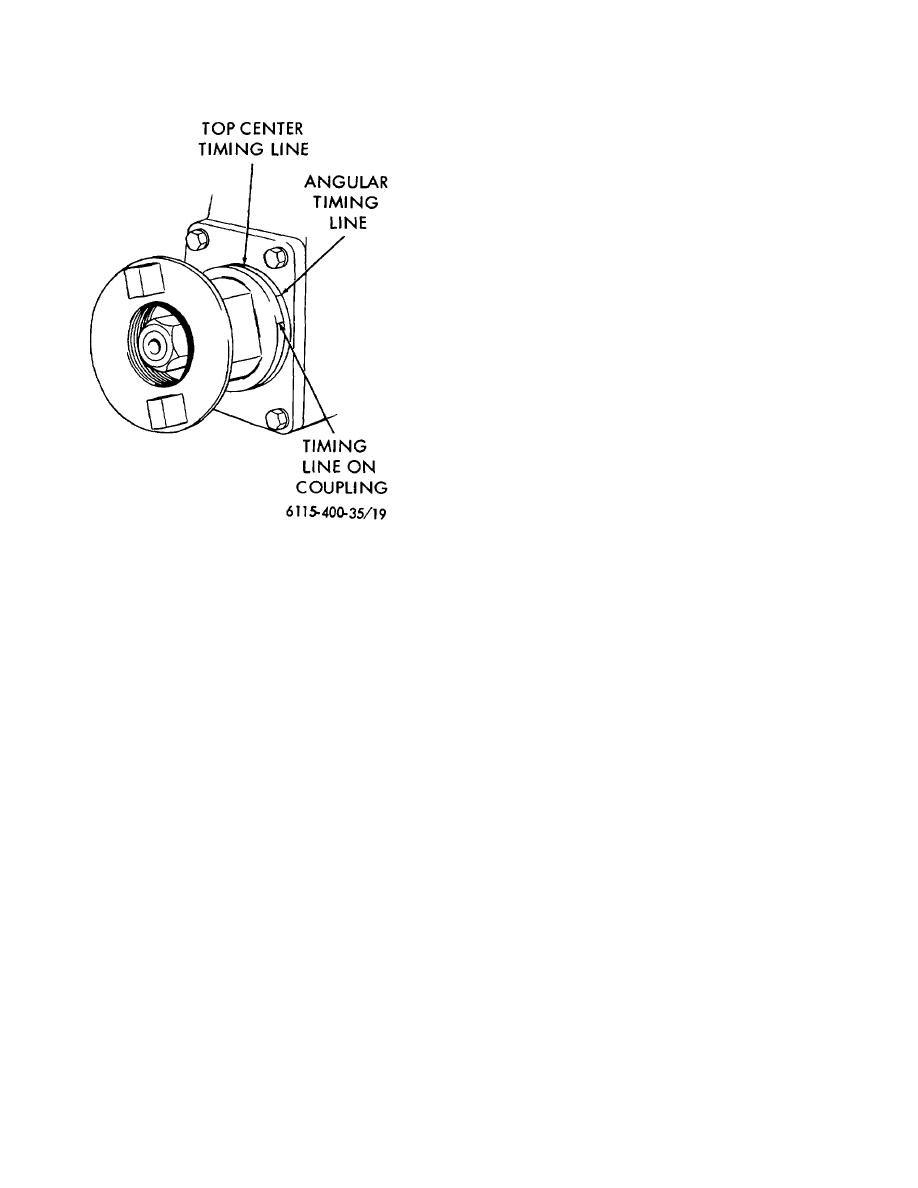

Figure 19. Fuel injection pump timing marks for

flowing when the graduated wheel on the

internal timing

test stand indicates 300 degrees. Add or

remove spacers as necessary.

Also

(7) Replace the delivery valve holder.

check each pumping element for proper

Manually turn the drive until number one

clearance between plunger and delivery

(1) plunger of the pump is in its lowest

valve body at top-dead-center.

position. The spill port now being open,

(15) Only one spacer is used between the

fuel will flow through the delivery valve

tappet and the tappet knob. Spacers are

holder.

furnished in sizes of 0.050, 0.054, 0.058,

0.062 and 0.066 inch.

Note. The pump must be rotated

counterclockwise for each timing

Note.

0.004 inch is about 1/2

operation to obtain accurate readings.

degree on the graduated wheel of the

Back-lash in test stand and pump parts

test stand.

may otherwise cause erroneous

settings,

far

beyond

specified

(16) Only 1/2 degree tolerance is allowed on

tolerances.

the fuel settings. If any deviation from

these figures is observed, the plunger

(8) Turn the pump counter-clockwise, through

must be adjusted.

the port opening position, just to the point

where the fuel stops flowing.

This

h. Calibrating the Fuel Injection Pump. Engine

indicates the port closing position.

performance depends to a great extent upon the

(9) The timing mark on the drive flywheel

accuracy with which the injection pump is calibrated.

should now coincide with the timing mark

pointer. Eliminate the old mark by filing,

if necessary, and establish a new one.

46