TM 5-6115-400-35

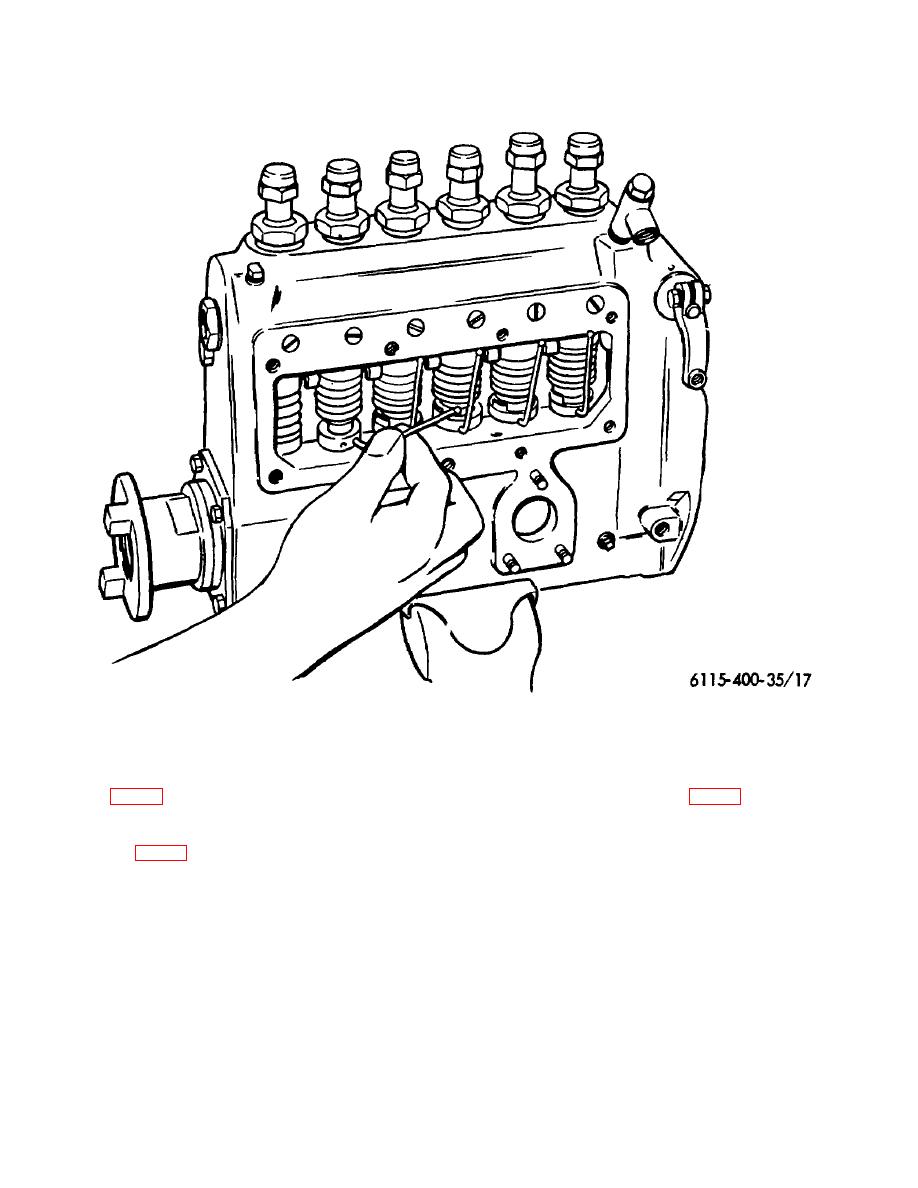

Figure 17. Remaining (or installing) temporary tappet retaining pins.

Note. Make certain timing line on coupling

(5) If adjustment is required, it can be accomplished

and No. 1 top center timing line coincide

through the raising or lowering the tappet with

adjusting spacers (49, fig. 15).

(6) Reinstall the delivery valve, spring and delivery

valve holder.

(3) Position a suitable screw driver under the knob

(51, fig. 15) of the tappet and raise the plunger

(7) The pump can now be timed internally in the

until it contacts the bottom of the delivery valve

manner outlined in subparagraph g, below.

body. Hold the plunger in this position and

(8) Mount pump on test stand and connect test oil

record measurement on depth gage or dial

lines for flow timing.

indicator.

(9) Inscribe a line on the pump end plate to

(4) The difference between the two figures

coincide with the line on the drive coupling to

represents the distance between the top of the

indicate the flowed position of this plunger, if no

plunger and the bottom of the delivery valve

mark is present, or a new end plate used.

body. This figure is generally (0.020 inch) with

Note. Never change timing mark on pump

limits of 0.012 inch to 0.028 inch.

coupling.

44