TM 5-6115-376-13

defective electronic synchronizer switch. Install

number one to operate until generator number two

electronic synchronizer switch in reverse order

is put on the line.

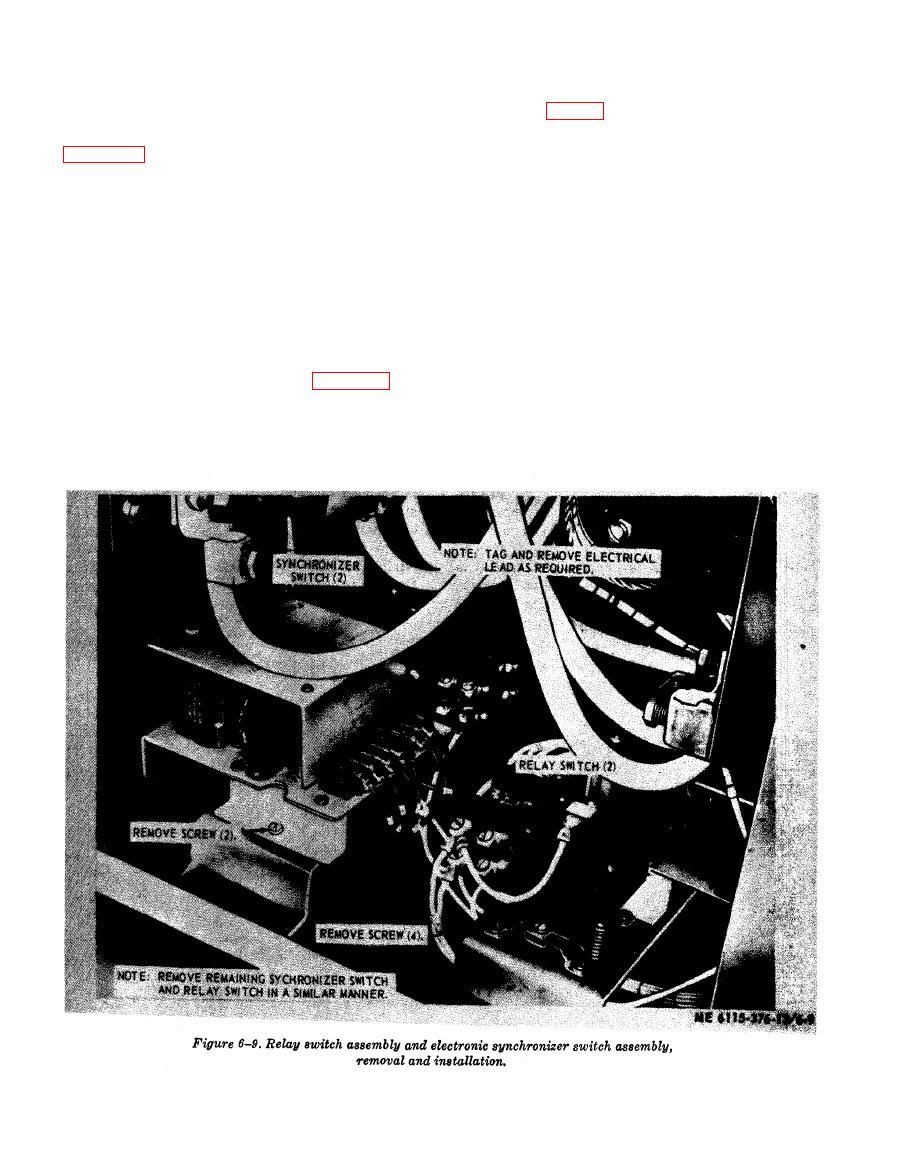

of removal (fig. 6-9). Install rear access panel.

g. Relay Switch Removal, Inspection and In-

stallation, Remove rear access panel, refer to

Switchbox (PU-699/M)

a. General. The switchbox is mounted on the

necessary; remove four mounting screws and re-

roadside fender of the PU-699/M. Its purpose is

move relay switch. Inspect all parts for damaged

to connect 3-phase power from one of two power

threads, cracks, breaks or other obvious defects.

sources (PU-699/M or PU-700/M, 60KW, gener-

Replace a defective relay switch. Install relay

ator sets) to a load. The power cable of the

switch in reverse order of removal; install rear

PU-699/M is connected to Gen 1 of the switchbox,

access panel.

and the power cable from the distribution box of

PU-699/M is connected to Load 1 of the switch-

h. Electronic Synchronizer Switch, The syn-

box. The power cable from the DE of the PU-700/

chronizer assembly contains two electronic syn-

M is connected to Gen 2 of the switchbox, and

chronizer switches of solid state design each

power cable from distribution box of PU-700/M

consisting of three plug-in type modules, t w o

is connected to Load 2 of the switchbox. Parallel-

transformers, transistors, diodes and capacitors.

ing of the two 60KW generator sets is automati-

Remove rear access panel. Refer to figure 6-9, tag

cally controlled. Control of power is by four

and disconnect electrical leads; remove two

circuit breaker switches.

mounting screws and remove electronic synchro-

b. Circuit Breaker Switches. The four circuit

nizer. Inspect all parts for cracks, breaks, loose

breaker switches on the switchbox should operate

connections, and other obvious defects. Replace a