TM 9-6115-604-34

NAVFAC P-8-633-34

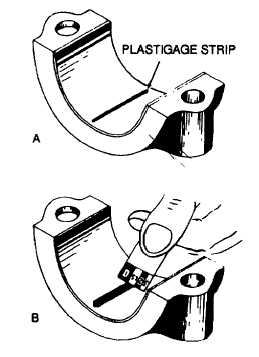

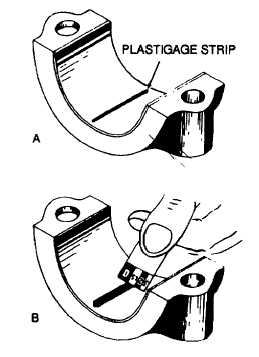

Figure 9-32. Using Plastigage to Determine Bearing Clearance

(6)

Remove the bolts (1), washers (2), and connecting rod cap (3). Compare the width of the compressed

Plastigage to the graduations on the Plastigage envelope (B. Figure 9-32). This is the connecting rod journal

clearance and must conform to the specifications in Table 1-4.

(7)

If the clearance is under the specifications given in Table 1-4, remove the bearings shells (11, Figure 9-24) and

check for oversize bearing shells, or the presence of foreign matter between the bearing shells and the

connecting rod (4) or cap (3).

(8)

If the clearance is over the specifications given in Table 1-4,install new bearing shells (11) and re-check the

clearance. If the clearance is still excessive, rebuild the crankshaft (32) in accordance with paragraph 9-28.

CAUTION

Before Installing the connecting rod bolts (1) and washers (2), coat the bolt threads, the

underside of the bolt heads, and the washers with clean lubricating oil MIL-L-2104. Failure to

do so will result In Improper torque and possible engine damage due to loosening of the

bolts.

(9)

If the clearance is satisfactory, remove all traces of Plastigage from the bearing shell and crankshaft journal,

lubricate the bearing shells and journal with a small amount of lubricating oil MIL-L-45199, and reinstall the

connecting rod cap (3), washers (2), and bolts (1). Tighten the bolts in accordance with Table 9-3.

(10)

Using a feeler gage, check the connecting rod side clearance. Connecting rod side clearance shall be 0.012 to

0.020 inch (0.30 to 0.51 mm), and the rods must be free to move sideways on the crankshaft (32). i the

connecting rods do not move freely on the crankshaft, or the clearance is not to specifications, check for

improper bearing shell installation or crankshaft thrust surface wear. Rebuild a worn crankshaft in accordance

with paragraph 9-28.

(11)

Repeat steps c through e, above, for each connecting rod bearing shell to be replaced.

9-60