TM 5-6115-593-34

NAVFAC P-8-631-34

TO-35C2-3-463-2

Air trapped in the fuel causes erratic performance and

hard starting. For this reason, piping must be

completely sealed against entrance of air and fine dust

or dirt.

17-62. Auxiliary tank fuel filters and sediment drains are

located in the set and are easily accessible to promote

regular and frequent service. Cleanliness of the fuel is

especially important on diesel engines which have easily

clogged, precision fuel injectors, and pumps.

17-63. Black iron pipe or copper tubing must be used

for diesel fuel systems galvanized tanks and piping must

not be used since the diesel fuel and the galvanized

coating react chemically to produce flaking which

quickly clogs filters or causes failure of the fuel pump or

injectors. Flexible lines must be of the type approved

for diesel fuels.

17-64. The auxiliary fuel tank should be vented so that

air and other gases can escape to atmosphere (see

figure 17-16 through 17-18). The vent must, however,

prevent dust, dirt, and moisture from entering the tank.

Where return lines are required, keep the return spaced

at least 12 inches (30.5 cm) away from the pickup or

fuel dip tube if this is not done, air bubbles could be

entrained in the fuel and cause erratic operation. At

least 5 percent of capability should be allowed in a

diesel main tank for expansion of the fuel. Auxiliary fuel

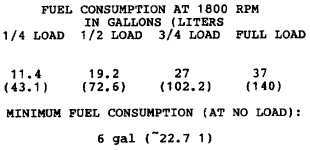

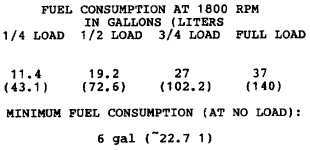

tank capacity can be computed by using table 17-6.

Table 17-6. Fuel Consumption for 500 KW DOD Generator Set

17-65. SET FUEL TANK. The capacity of the fuel tank

is determined by the fuel consumption of the unit and

the continuous operating time necessary. Fuel supply

capacity for generator service is 2 hours under full load

without refueling. All auxiliary tanks must have:

a. A vent line terminating above grade level in a

screened or hooded type vent cap with

unrestricted opening to atmosphere.

b. A fuel fill line terminating above grade level

and fitted with an appropriate cap or

terminating in a fuel filler box with an

appropriate cap and plainly marked for the

fuel utilized.

c.

A fuel supply line connected from the tank to

the electric fuel transfer pump.

d. The tank should be fitted with a foot valve

(permits flow in one direction only) to prevent

loss of transfer pump prime when the

transfer

pump is not in operation.

17-66. The auxiliary fuel oil transfer pump is an internal

part of the generator set and has the capacity to fill the

fuel tank in one hour when pumping fuel at a

temperature of 25°F (-31.7°C). Additionally, the pump is

capable of lifting fuel 10 feet (3 m) and provides

sufficient pressure to supply fuel through the filtration

system under all possible viscosities of the fuel.

17-20