TM 5-6115-593-34

NAVFAC P-8-631-34

TO-35C2-3-463-2

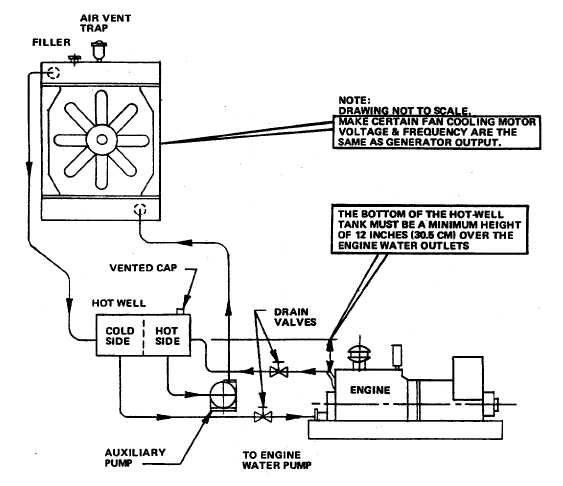

17-50. The surge tank should also be equipped with a

sight gauge, overflow pipe, and vent to atomosphere. It

should also have connections for makeup feed water.

17-51. Another important function of the surge tank is

the maintenance of a positive head of pressure on the

engine water pump inlet. The line connecting the

bottom of the surge tank to the engine water pump inlet

services this function.

17-52. The electric auxiliary water pump shown in

figure 17-14 is used to assist the engine driven pump in

maintaining the desired coolant flow rate which would

have been reduced in remoting the radiator by the line

and fitting drop incurred by the additional piping. In the

event of a failure of the auxiliary pump, a bypass valve

connected across the pump can be opened preventing

the complete loss of an emergency standby unit. No

component failure which by itself could prevent

operation should be overlooked.

17-53. A drain valve should be incorporated to facilitate

servicing the radiator. As shown in figure 17-14, the use

of a drain valve and water pump bypass valve permits

the draining of the radiator, surge tank, and the engine.

A strainer is used in the line returning from the radiator

to catch dirt, scale, and core sand.

17-54. The fan motor and electric auxiliary pump must

be connected to ensure their operation whenever the

unit is running.

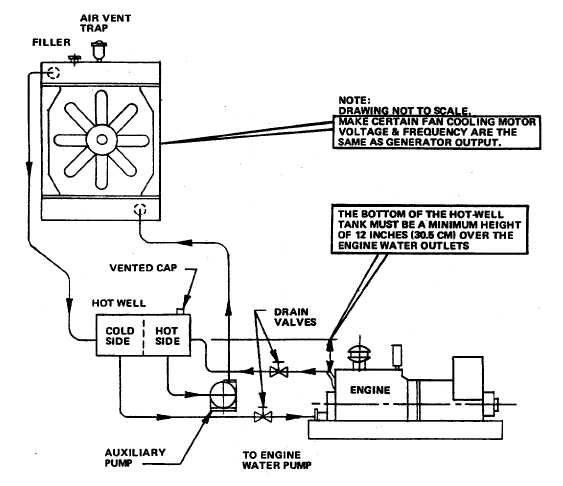

17-55. For applications in which the radiator is

positioned

at

some

distance

above

the

engine

centerline, a hot-well tank and an auxiliary water pump

are

Figure 17-15. Remote Radiator Application "C"

17-18