TM 5-6115-593-34

NAVFAC P-8-631-34

TO-35C2-3-463-2

top part of the top tank, from 1 to 3 inches (2.54 to 7.62

cm), so that a cushion of air is trapped here to take care

of normal surge.

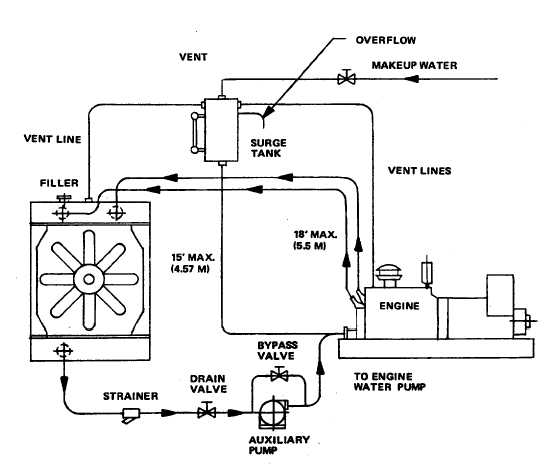

17-45. A strainer is used in the water line returning from

the radiator to catch dirt, scale, and core sand. The

electric auxiliary water pump shown in figure 17-13 is

used to assist the engine driven pump in maintaining the

desired coolant flow rate which would have been

reduced in remoting the radiator by the line and fitting

drop incurred by the additional piping. A drain valve

should be incorporated to facilitate servicing the

radiator.

17-46. The pipe size utilized should be the same size

as the radiator inlet an outlet fittings. Use the same pipe

size throughout the entire system. Use straight lengths

of pipe wherever possible in conjunction with radius

elbows wherever turns are required.

17-47. Flexible hoses used to isolate vibration should

be used at the inlet and outlets of both the engine and

radiator.

17-48. The fan motor and electric auxiliary pump must

be electrically connected to ensure their operation

whenever the unit is running.

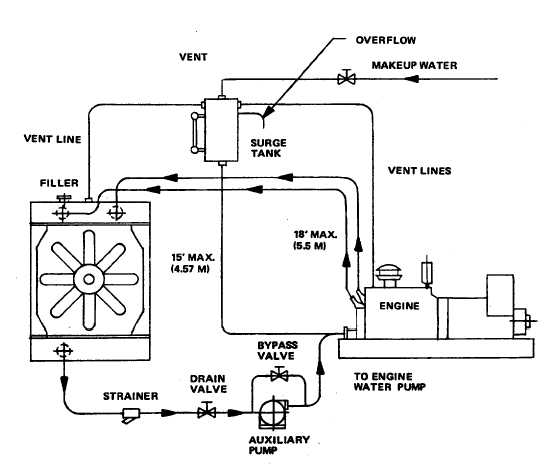

17-49. For applications in which the radiator is

positioned at some horizontal distance from the unit and

is not the highest point in the water system the

configuration shown in figure 17-14 is recommended.

The surge tank, located in a position elevated above the

radiator provides the space to accommodate the natural

expansion of heated water and the air and gases

trapped and dissolved in the water. The surge tank is

vented permitting escape of vapor and air.

Figure 17-14. Remote Radiator Application "B"

17-17