TM5-6115-593-34

NAVFAC P-8-631-34

TO-35C2-3-463-2

of engine, taking up all end play, and set

gauge at zero. The crankshaft must move

freely.

(13) Move crankshaft toward rear of engine. The

gauge should indicate 0.006 to 0.013 inch

(0.15 to 0.33 mm) end clearance for a new

engine, or an engine with new crankshaft and

new bearings.

(14) If end clearance is less than stated in step

(13), loosen capscrews slightly and shift

crankshaft toward front of engine, then toward

rear of engine. If capscrews have been

loosened, retighten as described in step (9).

Recheck end clearance.

NOTE

When an engine is being rebuilt,

always bring crankshaft end clearance

to 0.006 to 0.013 inch (0.15 to 0.33 mm)

by using standard new parts or by

using oversize thrust rings and a

reconditioned crankshaft.

(15) Bend in ear of each lockplate (37) against the

main bearing capscrew to lock it in place.

(16) Install and torque main bearing capscrews on

engines to the following values:

(a) Torque all right side capscrews to 70 to

75 foot-pounds (95 to 102 joules).

(b) Torque all left bank side capscrews to 70

to 75 foot-pounds (95 to 102 joules).

(c) Return to right bank and torque side

capscrews to 135 to 145 foot-pounds

(183 to 197 joules).

(d) Return to left bank and torque side

capscrews to 135 to 145 footpounds

(183 to 197 joules).

(e) Breakaway torque is 135 to 190 foot-

pounds (183 to 258 joules) in tightening

direction.

(17) Install camshaft bushings (23, figure 13-50)

using a bushing driver. Make certain that oil

passages between bushings and block oil

holes are properly aligned.

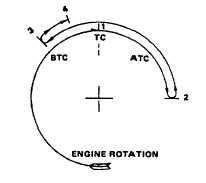

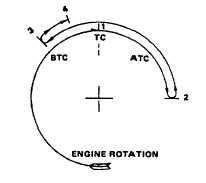

13. 35. INJECTION TIMING. After repair or overhaul,

the engine should be timed as follows:

NOTE

Timing No. 1 cylinder on right and left

bank will accomplish complete engine

timing. Repeat following steps for

each of the two cylinders.

a. Injector push tubes should be installed in their

sockets for timing operation.

b. Check No. 1 cylinder on each bank with injector

timing tool at 19 degrees before top center

firing position.

c. Install timing tool in place of injector with one rod

in push tube socket and with other rod resting

on piston. Follow procedures as shown on

figure 13-54 and steps e(1) through e(4), below.

The numbers on the diagram show check points

corresponding to numbered instruction steps.

Figure 13-54. Engine Injection Timing

Procedure Diagram

d. When indicator gauges are set at "0", they must

be near fully

13-105