TM5-6115-593-34

NAVFAC P-8-631-34

TO-35C2-3-463-2

removing only enough material to make

block usable.

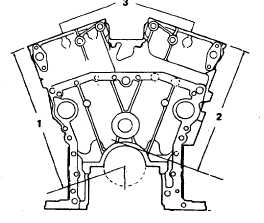

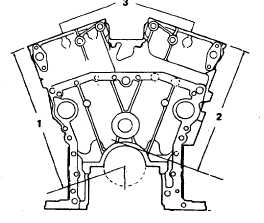

(c) Check distance from centerline of main

bearing to top of block (1, figure 13-52).

Refer to tabulated data in Chapter 1 for

dimensions.

(d) Finish surfaces to 125 rms.

(e) Resurface counterbore to obtain proper

linear protrusion. Check liner to block

contact in crevice seal area.

Figure 13-52. Cylinder Block Height

Checking Location

(7) Cylinder Head Capscrew Threads.

(a) Drill out old threads with 23/31 inch drill

to a depth of 1-7/8 inch drill to a depth

of 1-7/8 inches (47.63 mm) from the

cylinder block top surface.

(b) Tap drilled hole to a depth of 1-3/4 inch

(44.45 mm).

(c) Install heli-coil insert with inserting tool

until it is 1/2 inch (12.70 mm) below top

surface. Break off insert tang using a

punch and hammer, not an inserting

tool.

d.

Overhaul and Rebuilding of Cylinder

Block. Proceed as follows:

(1) Cylinder Liner Counterbore.

(a) Check upper liner counterbore and

remove burrs and dirt so liner will enter

cylinder block without distortion. If

counterbore exceeds limits listed in

Chapter 1 for the top 0.400 inch (10.16

mm) depth, mark block for counterbore

repair. The counterbore ledge must be

smooth and perpendicular to the liner

bore to within 0.005 inch (0.13 mm)

total

indicator

reading.

Use

straightedge to check flatness of top of

block.

(b) Check counterbore depth so installed

liner will be assembled to correct

protrusion and to determine if refinish of

counterbore

surface

is

necessary.

Depth of counterbore in a new block is

listed in Chapter 1. If worn to or beyond

limit,

the

cylinder

block

must

be

salvaged. If worn less than worn limit,

the surface can be refinished and shims

installed under the cylinder liner to

restore proper protrusion. Refinished

counterbore radius must be 0.025 to

0.30 inch (0.63 to 0.76 mm).

(c) Installed cylinder liners must protrude

0.003 to 0.006 inch (0.08 to 0.15 mm)

above block. To check for proper

protrusion without installing a liner,

proceed as follows:

1.

Measure liner flange outside bead

with micrometer. Do not include

bead on top of liner flange in taking

measurement.

2.

Measure block counterbore

13-100