TM5-6115-593-34

NAVFAC P-8-631-34

TO-35C2-3-463-2

d.

Repair. Repair by replacing any worn or

damaged valves and springs, as determined in

paragraph b and c above.

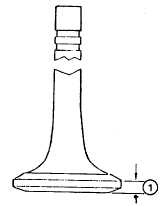

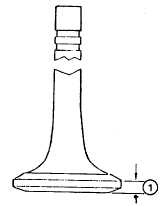

Figure 13-45. Minimum Valve Head Rim Thk.

e.

Installation.

(1) Lubricate valve stem with 140W lubricating

oil and insert valve into valve guide.

(2) Place cylinder head face down on a wooden

bench or protective surface to prevent

marring of milled surface.

(3) Assemble lower valve spring guide over

valve guide.

(4) Assemble springs. Install, if required, up to

1.16 inch (1.59 mm) of spacers to reduce

valve spring length.

(5) Assemble upper valve spring retainer.

Compress valve springs and install new half

collets.

13-29. INTAKE AND EXHAUST VALVE SEATS. Refer

to paragraph 13-27 for procedures covering inspection

and replacement of the intake and exhaust valve seats.

13-30. CYLINDER HEAD. Refer to paragraph 13-27

for

procedures

covering

inspection,

replacement,

overhaul, and rebuilding of the cylinder head.

13-31. VALVE LIFTERS. Refer to paragraph 13-25 for

inspection and replacement of the valve lifters (levers).

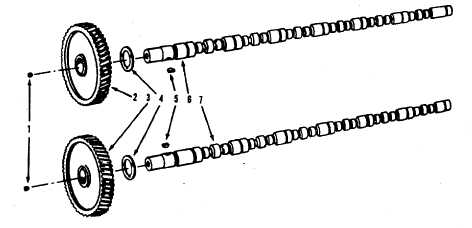

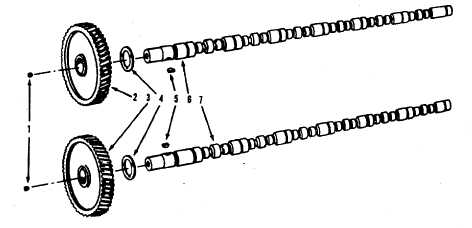

13-32. CAMSHAFT. Refer to figure 13-46 and proceed

as follows:

a.

Removal.

(1) Remove push rods and tappets as specified

in paragraph 13-26.

(2) Remove

gear

cover

as

specified

in

paragraph 13-23.

LEGEND

1.

Plug

5.

Key

2.

Gear

6.

Camshaft

3.

Gear

7.

Camshaft

4.

Washer

Figure 13-46. Camshafts, Exploded View

13-88