TM5-6115-593-34

NAVFAC P-8-631-34

TO-35C2-3-463-2

CAUTION

Special care must be used to avoid

breaking carbide tips. Sharpen tipped

tools on a diamond-impregnated wheel.

(15) Remove crosshead guides marked for

replacement using a dowel puller.

(16) Using a crosshead guide mandrel, press

new guides into cylinder head to obtain

protrusion of 1.860 to 1.880 inch (47.24 to

47.75 mm).

(17) If crosshead guide bore is worn or

mutilated, install oversized guides as

follows:

(a) Drill guide bore in head to original depth

with a 29/64-inch drill.

(b) Lubricate and ream bore with a 15/32-

inch reamer.

(c) Install

oversized

guide

until

guide

protrusion is 1.860 to 1.880 inches

(47.24 to 47.75 mm).

(18) Remove loose or excessively worn valve

seat inserts by striking insert sharply with a

chisel, causing it to crack and release the

press fit. Remove all inserts if head has

been resurfaced.

CAUTION

Cover the valve seat with a rag to avoid

injury from broken pieces of the seat.

(19) Enlarge counterbore to next oversize using

valve seat insert cutter. Inserts are

available in standard and oversizes as

tabulated in Chapter 1.

NOTE

If head was resurfaced and standard

inserts

are

to

be

used,

deepen

counterbore only.

(20) A valve seat insert tool must be used to

hold and drive cutters.

(21) Cut counterbore 0.006 to 0.010 inch (0.15

to 0.25 mm) deeper than insert thickness to

permit peening of head to hold insert. It is

important to allow cutter to dwell for

several revolutions upon reaching proper

depth in order to ensure a perfectly flat

surface at the bottom for the insert to seat

on.

(22) Install valve seat insert and peen around

insert at least five places with a 1/4 inch

(6.35 mm) diameter round end punch.

(23) After

checking

condition

of

grinding

equipment, grind valve seats holding

seating

motor

as

nearly

vertical

as

possible.

(24) Check valve seat which should be 1/16 to

1/8 inch (0.159 to 3.17 mm).

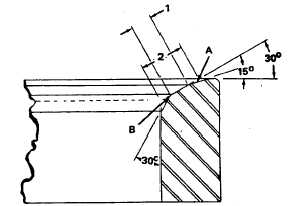

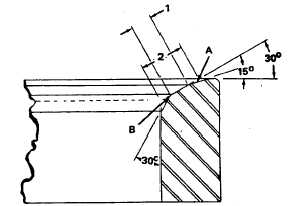

(a) If seating area (2, figure 13-44) is wider

than 1/8 inch (3.175 mm) maximum,

stock can be removed from points "A"

and "B" with specially dressed valve

seat grinder stones.

(b) Narrowing should not extend beyond

chamfer on seat insert. Chamfer

provides for peening metal.

Figure 13-44. Valve Seat Insert, Cross Sections

(25) Dress wheel for final finish.

13-84