TM5-6115-593-34

NAVFAC P-8-631-34

TO-35C2-3-463-2

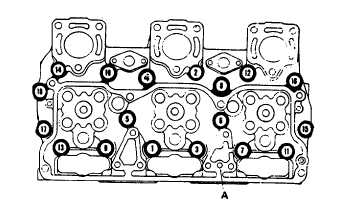

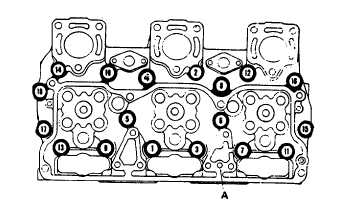

Figure 13-42. Head Capscrew Tightening Sequence

c.

Inspection.

(1) Check valve seats and injector sleeve for

cracks. Discard cylinder head if cracked.

(2) Check all valve springs for damage.

(3) Check for signs of metal erosion around

water holes.

(4) Check cylinder head for worn or uneven

surface at point of contact with gasket.

(5) Examine fuse plug for signs of overheating.

If plug shows signs of overheating, check

for further damage and replace if necessary.

d.

Repair.

(1) Replace any damaged valve springs.

(2) Insert sleeves into water holes that have

become enlarged due to metal erosion.

Refer to paragraph 13-27 f.

(3) Resurface head surface that is deeply

scratched or worn. Rework valve seat insert

counterbore by removing amount of stock

equal

to

that

removed

during

head

resurfacing operations. Refer to paragraph

13-27 f.

(4) If exhaust ports are not flat, resurface

exhaust ports. Exhaust ports should not be

more than 0.003 inch (0.08 mm).

e.

Overhaul.

(1) Using a valve spring compressor, compress

valve springs (6), remove half collets (3),

retainers (5), spring (6), valve spring guides

(7), and guides (9).

NOTE

Perform the necessary tests to determine

the extent of overhaul or the scope of

rebuilding required to the cylinder head.

(2) Hydrostatic Testing

(a) Install injector sleeve holding tool or a

scrap injector assembly in each injector

sleeve. Tighten tool or injector hold-

down capscrews to 10 to 12 foot-pounds

(14 to 16 joules) torque to seal lower

end of injector sleeve and place cylinder

head

in

the

hydrostatic

tester

or

equivalent.

WARNING

OVERHEAD

OPERATIONS

HAVE

INHERENT HAZARDS THAT CANNOT BE

MECHANICALLY SAFEGUARDED. HARD

HATS

AND

SAFETY

SHOES

ARE

REQUIRED.

(b) Use hoist to position head and tester

over

13-80