TM5-6115-593-34

NAVFAC P-8-631-34

TO-35C2-3-463-2

(3) Install vibration damper (3) and fasten with

washer (2) and screw (1); torque screw to

450 to 500 foot-pounds (610 to 678 joules).

(4) Install six screws securing vibration damper

(3). Torque conical screws to 70 to 80 foot-

pounds (95 to 108 joules). Torque hexagon

head capscrews to 100 to 120 foot-pounds

(136 to 163 joules).

NOTE

Crankshaft must be kept to front or rear

limit of thrust clearance while wobble is

being checked.

CAUTION

Do not pry against or strike damper.

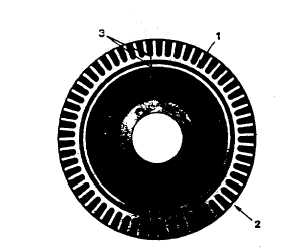

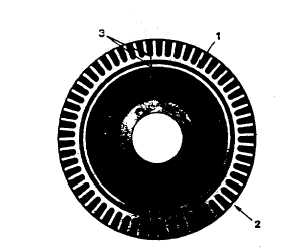

(4) With a dial gauge mounted to gear case

cover and arm resting on the inner

machined surface of the outer member,

check vibration damper eccentricity and

wobble at points (1) and (2) as show in

figure 13-32. Wobble must not exceed

0.009 inch (0.23 mm) per inch of radius.

Eccentricity must not exceed 0.030 inch

(0.76 mm).

Figure 13-32. Vibration Damper Wobble Check

Points

13-19.

ENGINE FRONT SUPPORT. To inspect and

replace the engine front support, refer to figure 13-33,

and proceed as follows:

a. Inspection. Inspect the engine front support for

signs of cracking or other signs of damage.

Replace if necessary, as follows:

b.

Removal.

(1) Refer to Chapter 2, Section IV to remove

engine assembly.

(2) Remove screws (4), lockwashers (5), screws

(6), and lockwashers (7).

(3) Remove

screws

(1),

nuts

(3),

and

lockwashers (2).

c.

Installation.

(1) Install new engine front support screws (1),

lockwashers (2), and nuts (3).

(2) Replace engine assembly.

(3) Install

lockwashers

(7),

screws

(6),

lockwashers (5), and screws (4).

13-20

OIL PAN ASSEMBLY. To replace or repair the

oil pan assembly, refer to figure 13-34, and proceed as

follows:

a.

Removal.

(1) Drain

oil

in

accordance

with

the

Operator/Crew

and

Organizational

Maintenance manual.

(2) Disconnect temperature sensor (34, figure

13-34) electrical connector. Remove screw

and washer securing temperature sensor

cable clamp, then move and secure cable

away from work area.

(3) Disconnect engine preheat hose coupling on

radiator line and two couplings on preheater

assembly, then remove three screws and

washers securing preheat hose support

brackets to engine. Move and secure

preheat hoses away from work area.

(4) Remove four nuts and washers from

preheater assembly V-bolts, then move and

secure preheater assembly away from work

area.

13-64