TM5-6115-593-34

NAVFAC P-8-631-34

TO-35C2-3-463-2

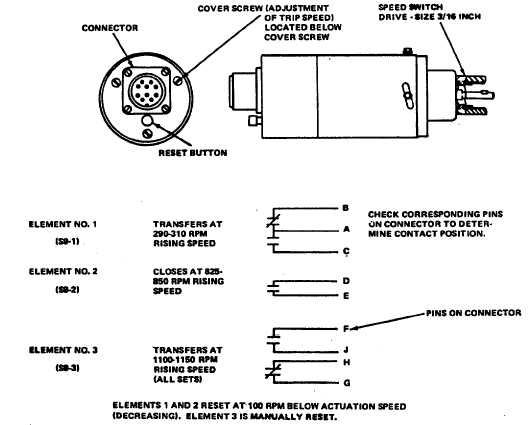

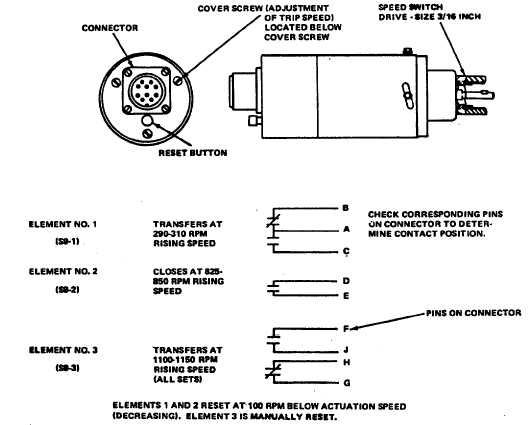

drive speed gradually and observe that the

contacts close in the 290 to 310 range.

(5)

Connect ohmmeter leads across pins D and E

and verify an open circuit. Increase drive speed

and observe that elements S9-2 (contacts D and

E) closes in the speed range of 590 to 610 rpm.

Gradually reduce speed to 490 minimum rpm.

Observe that element S9-2 resets to the

condition shown in figure 13-2.

(6)

Connect ohmmeter across pins H and G

connector and verify a closed circuit. Increase

drive speed gradually. The contacts should

open at a speed of 1100 to 1150 rpm. Hold

drive speed and read contacts F and J. Meter

should indicate a closed circuit. Reduce drive

speed to less than 1000 rpm, press the manual

reset switch and observe with the meter that

element S9-3 contacts reset to the condition

shown in figure 13-2.

(7)

To obtain the required performance

characteristics during tests (3) through (6),

adjustments can be made. By loosening screws

(1, figure 13-1) and rotating the cap and cover

assembly relative to the body assembly, the trip

points of all those elements can be raised or

lowered. In addition, the trip speed of each

individual element can be raised or lowered by

removing cover screws as shown in figure 13-2

and turning appropriate set screw located

beneath cover screws with a 1/16 inch Allen

wrench.

Figure 13-2. Speed Switch Sensitivity Tests (Mechanical Type Switch) (Code “A")

13-3