TM5-6115-593-34

NAVFAC P-8-631-34

TO-35C2-3-463-2

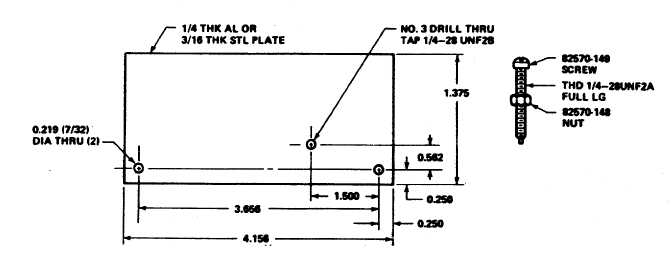

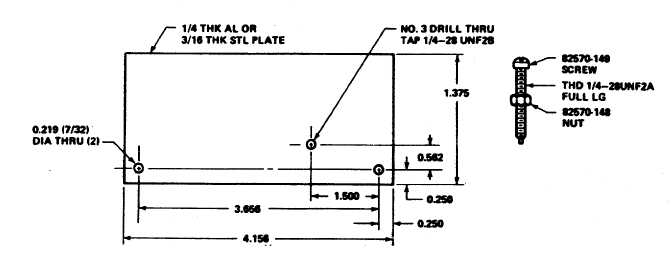

Figure 12-1. Speed Setting Adapter Plate

with the shaft hole in the droop lever (33).

(7)

Close needle valve (92) 1/4 to 1/2

turn from bottoming to stabilize unit.

(8)

Check governor section for leaks,

hunting, drifting and oil pressure.

c.

Governor Needle Valve Setting. Eliminate any air

trapped in the actuator passages if not already done

in the preliminary set-up. With the governor

controlling, open needle valve (92) until the unit hunts

or surges. After 2 or 3 minutes, gradually close the

needle valve until the speed just settles out. Closing

the needle valve further than necessary makes the

unit slow to return to set speed after a load change.

Never close the needle valve tight. Test the unit by

manually disturbing the speed. Only a small

overshoot or undershoot should occur before the unit

returns to its steady-state speed. The actuator has no

needle valve adjustment.

d. Speed Droop Adjustment. Speed droop is adjustable

internally. The speed droop bracket (32) is clamped

to the speed droop lever with a setscrew. A pin on

the droop bracket carries the floating lever (19).

When this pin is aligned with the droop lever shaft the

droop will be

zero. Move the speed droop bracket towards the ballhead

to increase droop. Speed droop is normally set in the

range of 3 to 6 percent.

e.

Centering Pilot Valve Plunger.

(1)

Adjust speed adjusting screw until

governor is approximately 5 percent above

steady-state speed.

(2)

Disconnect test stand linkage

from terminal shaft.

(3)

Back out actuator pilot valve

plunger screw (63) 1-1/2 to 1-3/4 turns after

bottoming very carefully against spring.

Use a 7/64 inch (2.8mm) hex wrench.

(4)

Set test circuit (figure 12-2) to

OFF and connect to transducer plug on

actuator case.

(5)

Connect a 9 VDC power source

to test circuit. Set test circuit to CENTER.

(6)

Adjust test circuit potentiometer

to 400 ma then set switch to OFF.

(7)

Adjust spring seat screw (56) with

a 1/8 inch (3.2 mm) hex wrench until

terminal shaft rotates approximately to its

midpoint of travel. Turn spring seat screw

(56) clockwise to move terminal

12-2