TM5-6115-585-34

NAVFAC P-8-262-12

TO-35C2-3-455-2

TM-05684C-34

1. Oil base

12. Center cam-shaft bearing

24. Shim

2. Gasket

13. Rear camshaft bearing

25. Thrust washer (2)

3. Screw (10)

14. Plug

26. Keys (3)

4. Lockwasher (10)

15. Retaining ring

27. Bolt (2)

5. Washer (10)

16. Crankshaft washer

28. Washer (2)

6. Bolt (8)

17. Crankshaft gear

29. Center bearing housing

7. Bearing (8)

18. Packing

30. Dowel

8. Cap (4)

19. Rear bearing plate

31. Lower bearing

9. Connecting rod (4)

20. Screw (6)

32. Upper bearing

10. Piston assembly (4)

21. Lockwasher (6)

33. Crankshaft

11. Front camshaft bearing

22. Crankshaft end bearing (2)

34. Cylinder block

23. Gasket

TS

6115-585-34/7.15(2)

Figure 7-15. Crankshaft Pistons and Connecting Rod (Sheet 2 of 2)

NOTE

The connecting rod and cap are stamped for

installation in the proper cylinder. When re -

moving piston assemblies, check the marking

so each piston can be installed in the proper

cylinder.

b. Removal (see figure 7-15).

(1) Drain crankcase oil and remove oil base (1)

and gasket (2) by removing screw (3), lockwasher (4)

and washer (5).

(2) Remove screws (13, figure 7-19), lockwasher

(12), bracket (11) and remove oil cup assembly (10).

(3) Remove cylinder head (paragraph 7-9) and

remove all carbon at the top of the cylinder bore. Re-

move ridge from cylinder bore before removing

piston.

(4) Remove bolts (6, figure 7- 15), cap (8) and

bearings (7) from each connecting rod (9) and push the

piston assembly (10) upward through top of cylinder

bore with a soft wooden tool to prevent rod bearing

damage. Loosely install cap (8) and bearings (7) on

the corresponding removed piston assembly to main-

tain proper grouping.

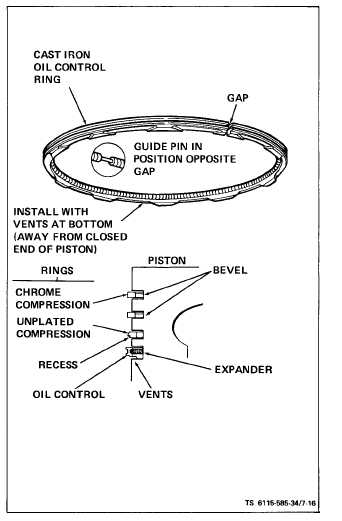

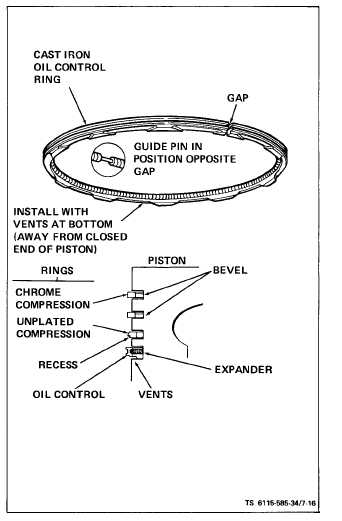

c. Disassembly (see figure 7-14).

(1) Using a ring expander, remove piston rings

(1, 2 and 4) and oil ring expander (3) from each piston.

(2) Remove two retaining rings (5) and push piston

pin (6) from each piston.

d. Inspect and Repair.

(1) Pistons. Thoroughly clean and inspect each

piston. Clean carbon from ring grooves and be sure

all oil holes are open. If any piston is badly scored

or burred, loose in cylinders, has badly worn ring

grooves or otherwise is not in good condition. redate

it. Check the piston clearance- in cylinder 90° “from

axis of piston pin and below oil control ring (4, figure

7- 14). Clearance should be 0.0062 to 0.0082 inch. If

not, replace piston and check cylinder wall for possi-

ble reconditioning.

(2) Piston Pins. Each piston pin should be a

thumb push fit into its piston at room temperatures.

Figure 7-16. Piston Ring Installation

7-17