After

main

using

NOTE

installation of new connecting rod or

bearings, clearances should be checked

plastic gauge.

(5) Install oil base (1, figure 7-15) with a new

gasket (2) using screws (3), lockwasher (4) and

washer (5).

(6) Install cylinder heads using proper bolt tight-

ening sequence (see figure 7-13).

7-11. OIL PUMP.

a. Remove.

(1) Refer to paragraph 7-14 and remove gear

cover.

(2) Refer to paragraph 7-10 and remove oil base

assembly and oil cup assembly.

(3) Remove crankshaft gear lock ring (14, figure

7-19), gear (16) and retaining washer (15). At this

time the crankshaft gear (16) should be inspected for

signs of wear.

(4) Hold the pump (19) while removing attaching

screws (17) and lockwashers (18). Remove pump.

b. Clean and Inspect.

(1) Inspect oil passages. Clean with stiff wire

and wash out with fuel oil if necessary.

(2) Rotate pump drive gear and check that it ro-

tates smoothly without binding.

c. Install (see figure 7-19).

(1) Install gear (16), retaining washer (15), and

lockring (14).

(2) Fill pump intake and outlet with oil to be sure it

is primed.

(3) Mount pump on engine using screws (17) and

lockwashers (18). Allow pump drive gear to crank-

shaft gear clearance. Failure to allow clearance can

damage oil pump.

(4) Install oil cup assembly (10) into pump.

(5) Install bracket (11) on center main bearing

housing and secure with lockwasher (12) and screw

(13).

(6) Install oil base (refer to paragraph 7-10).

(7) Install gear cover (refer to paragraph 7-14).

7-12. OIL FILTER ADAPTER ASSEMBLY.

a. Removal.

(1) Refer to the Operator/Crew and Organiza-

tional Maintenance Manual and remove the oil filter,

TM5-6115-585-34

NAVFAC P-8-262-12

TO-35C2-3-455-2

TM-05684C-34

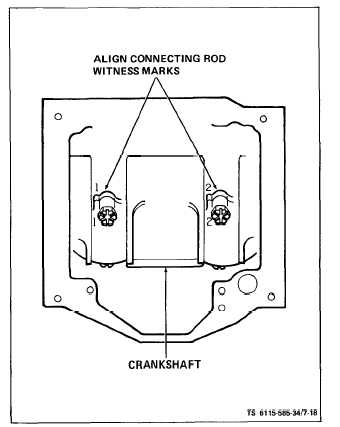

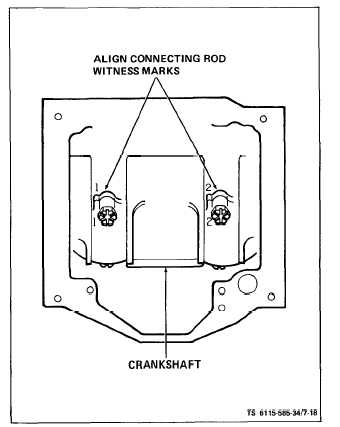

Figure 7-18. Connecting Rod Installation

oil pressure switch and oil lines connected to the oil

filter adapter.

(2) Remove screws (23 and 24, figure 7-19) and

lockwashers (25) and remove oil filter adapter (26)

and gasket (27). Discard gasket.

b. Inspection. Clean and inspect oil filter adapter

for damaged threads. Check oil passages for obstruc-

tion and clean if necessary.

c. Installation.

(1) Clean all gasket material from oil filter

adapter (26, figure 7-19) and cylinder block. Attach

oil filter adapter (26) and new gasket (27) to cylinder

block with screws (23 and 24) and lockwashers (25).

(2) Refer to the Operator and Organizational

Maintenance Manual and install the low oil pressure

switch, oil filter and oil lines on the oil filter adapter.

7-13. OIL BY-PASS VALVE.

a. Test on Equipment (see figure 7-20). High oil

pressure may be caused by the by-pass valve plunger

sticking closed. Low oil pressure may be caused by

the by-pass valve plunger sticking open. If these con-

ditions exist, clean and inspect by-pass valve.

7-19