TM5-6115-585-34

NAVFAC P-8-262-12

TO-35C2-3-455-2

TM-05684C/05685B-M

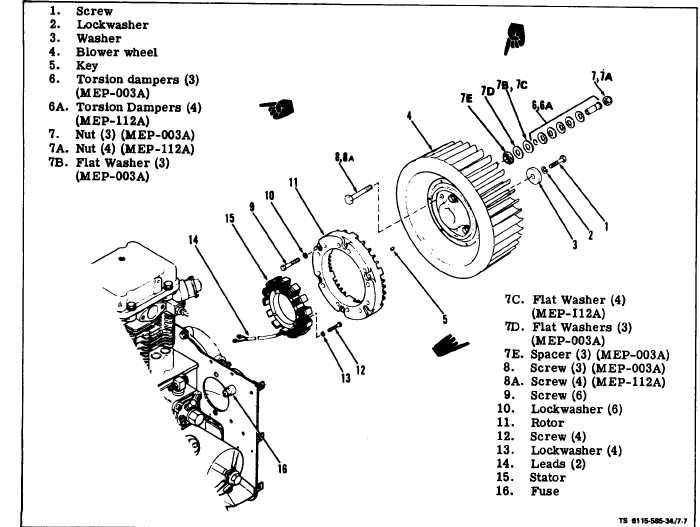

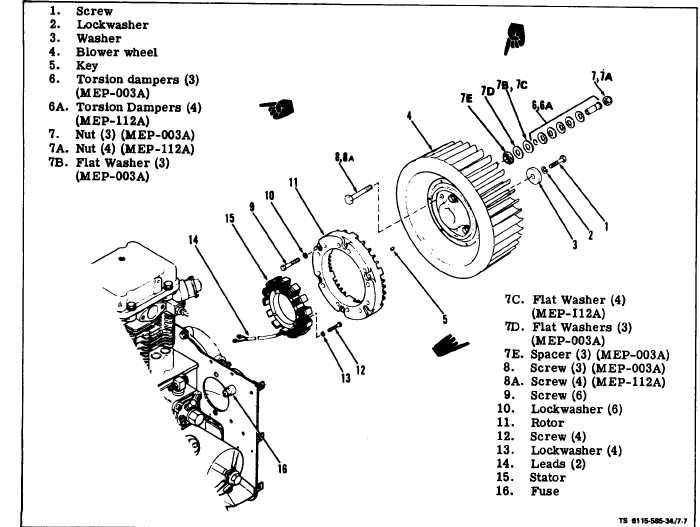

Figure 7-7. Battery Charge Alternator and Blower Wheel

(1) Plug the oil cooler outlet using suitable plug.

NOTE

(2) Connect the oil cooler in suggested test set-

up (see figure 7-6).

Observe the arrangement of the conical

washers in the torsion damper assemblies.

(3) Apply 25 psi air pressure to the oil cooler.

These washers must remain ‘in the same ar-

(4) Close the valve and monitor the pressure. A

rangement of the originally assembled set or

drop in air pressure indicates a leak in the oil cooler.

the function of the dampers will be impaired.

7-7. BLOWER WHEEL ASSEMBLY.

a. Inspect (see figure 7-7).

(1) Refer to Operator and Organizational

Maintenance Manual and remove blower housing.

(2) Check blower wheel (4) for cracks or broken

fins. Check for free play between blower wheel and

hub. Replace torsion damper assemblies (6) if free

play is present.

b. Removal. Remove screw (l), lockwasher (2) and

washer (3), attaching blower wheel to crankshaft. Use

two 5/16-24 screws in blower hub and a suitable

c. Repair. Blower wheel and hub are a balanced

unit and should not be disassembled. To replace tor-

sion damper assemblies, remove screws, nuts, and

replace torsional dampers and reuse flat washers

and spacers as required for that type set. Torque

screws 28-30 ft-lb.

d. Install.

(1) Mount blower wheel assembly to crankshaft

using screw (l), lockwasher (2) and washer (3). Torque

screw (1) to 65-70 ft-lb.

(2) Refer to Operator and Organizational

puller to remove blower wheel (4) and key (5).

Maintenance Manual and install blower-housing.

Change 2 7-7