e. Replace. Using screws (13, figure 7-2), lock-

washers (14), and nuts (15), attach governor control

bracket (12) to engine back plate. Attach speed control

cable (11) to governor arm (3) with pin (6) and cotter

pin (5). Attach governor arm (3) and governor linkage

(1) between governor and fuel injection pump (2). If

new ball joints are used on linkage, position the new

joints to obtain the same length or 1/32 inch more (1

turn = 1/32 inch) than the old linkage. If old linkage

length is not available, position new ball joints about

midway on each end linkage, then lengthen 1/8 inch.

DO not overspeed engine for

moment.

more than a

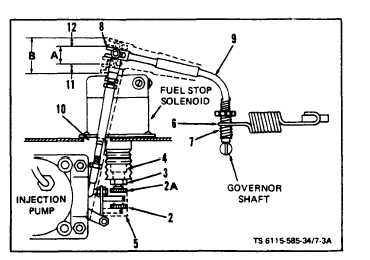

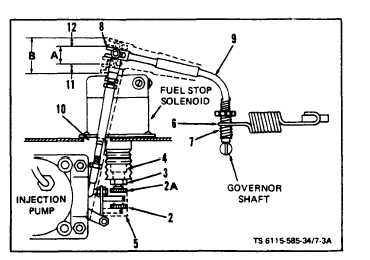

f. Preliminary Linkage Adjustment (figure 7-3.1).

The following adjustments shall be made before

starting the engine if the linkage was replaced.

(1) With link (1) compressed, adjust length be-

tween ball joints to 5-1/2 in.

(2) Set solenoid bumper screw to shut off posi-

tion, dotted line (2), by loosening locknut (3) on sole-

noid plunger (4). With plunger down, adjust bumper

screw to push control unit post down, dotted line (5),

to maximum shutoff position.

(3) Hook governor spring (6) in the mid-range of

sensitivity ratchet (7).

(4) Manually move governor arm and linkage to

check for interference.

(5) Adjust position of upper ball joint in slot

(8) on governor arm (9) so link (1) does not bind

against fuel stop solenoid or hole (10). A slight con-

tact of link to bottom of solenoid is permissible but

only at shut down. The fuel control unit should move

up to position (2A) when solenoid is energized with

start switch.

g. Final Linkage Adjustment. Perform the follow-

ing steps to establish governor overshoot and under-

shoot, balancing external linkage movements within

the range of governor internal parts.

(1) Start engine and, with no load, adjust speed

control for rated frequency.

(2) Push linkage downward (11) about 1/4 in.

with light finger pressure. If the linkage appears to

reach governor internal travel limit (higher pressure

is felt), stop engine and lengthen linkage as required.

(3) Apply rated load and adjust speed control

for rated frequency.

CAUTION

Shortening the linkage too much in the follow-

ing step will prevent no-load speed control,

or may cause a runaway engine.

h. Speed Droop Adjustment (figure 7-3.1 ). Droop

between no load and rated load is adjusted by ro-

tating ratchet (7).

Clockwise rotation decreases

droop; counterclockwise rotation increases droop.

Start engine and with no load, adjust speed control

for rated frequency. While observing the set fre-

TM5-6115-585-34

NAVFAC P-8-623-34

TO-35C2-3-455-2

TM-05684C/05685B-34

quency meter, change from no load to full load several times. Adjust to

minimum droop obtainable. Repeat as required. On ASK equipped gen-

erators, refer to Operator and Organizational Maintenance Manual and

replace right panel assembly.

Figure 7-3.1. Governor Linkage Adjustment

NOT E

If droop is too small, hunting (periodic fre-

quency swings) will occur when changing from

no load to full range because the governor

will be too sensitive.

7-4. FLYWHEEL AND RING GEAR ASSEMBLY

a. Removal (see figure 7-3).

(1) Remove engine from set per paragraph 2-9.

(2) Remove timing pointer (10, figure 7-3) by re-

moving screws (11).

(3) The flywheel (1) is a tapered fit on the

crankshaft (2). Remove flywheel mounting screw (3)

and washer (4). Support and remove flywheel and ring

gear assembly by using a two pronged wheel puller

inserted through the slots provided in the flywheel.

b. Clean and Inspect. Clean the flywheel and ring

gear assembly (1) using solvent. Check the ring gear

for broken or worn teeth.

c. Install. Replacement flyheels are supplied with

timing marks already stamped in place. The engine

must still be timed properly to this timing mark. The

only accurate method of determining the port closing

point is to measure piston travel. This is a critical

measurement and should be done only with accurate,

dependable equipment Mount flywheel keying

properly and tighten in place using screw (3) and

washer (4), (figure 7-3). With the flywheel mounted,

rotate flywheel counterclockwise until Number 1

cylinder is on its compression stroke, which follows

the closing of its intake valve. Remove the exhaust

rocker arm (3, figure 7-9), exhaust valve rotator (1,

figure 7-11). valve looks (2), spring retainer (3) and

spring (5), using fabricated tool (see figure 7-10).

Allow exhaust valve to drop down onto top of piston.

Rotate flywheel counterclockwise until piston is at

Change 6

7-5