ME 6115-545-34/14-45

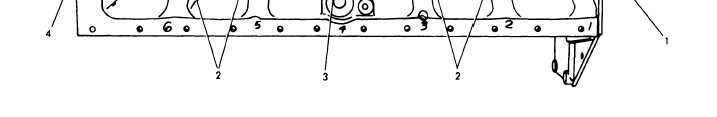

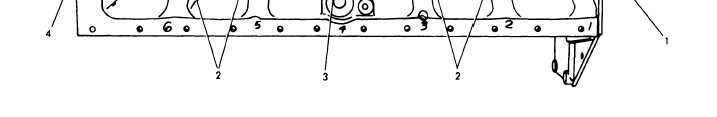

1. Front main bearing cap

3. Center main bearing cap

2. Intermediate main bearing caps

4. Rear main bearing cap

CAUTION

Figure 14-45.

MainBearing Caps

Make certain the backs of bearing shells are

free from dirt and grit particles.

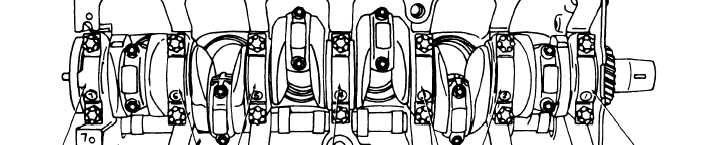

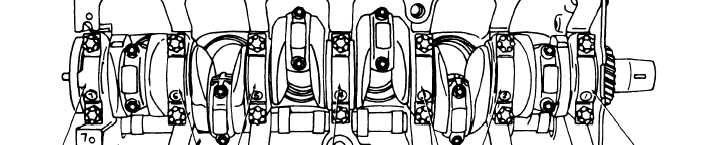

(2) Lubricate all crankshaft main bearing jour-

nals with engine oil; lower the crankshaft into position

in the cylinder block with flywheel flange end of crank-

shaft toward the rear.

CAUTION

Make certain that timing mark on crankshaft

gear is aligned with timing mark on camshaft

gear, when crankshaft is installed.

(3) Place the lower halves of the main bearing

shells in position in the main bearing caps.

CAUTION

Make certain the backs of the bearing shells

are free from dirt and grit particles.

(4) The bearing caps are numbered 1,2,3, etc.

indicating their respective positions. Before instal-

ling center main bearing cap, insert upper thrust

flanges (flanges without dowel pin holes) with oil

grooves of thrust flanges located next to cheeks of

the crankshaft. Position lower thrust flanges on

dowel pins, with the oil grooves in the thrust flanges

to the outside of the bearing cap.

(5) Install main bearing caps with numbers

facing camshaft side of the engine and corresponding

to number stamped on lower edge of cylinder block

as shown in figure 14-45. Install the main bearing

cap attaching lock bolts snugly. Force crankshaft

in both directions to align the bearing caps with the

upper portion of the main bearing bores.

(6) Using a torque-indicating wrench, tighten

the main bearing cap lock bolts to a torque of 170 to

190 foot-pounds.

CAUTION

Do not overtighten main bearing lock bolts.

If these lock bolts are overtightened, bear-

ing caps may be distorted, causing bearing

to be drawn tight against the crankshaft and

premature failure will result. The crank-

shaft should turn freely after all capscrews

are properly torqued. Never file or shim

a bearing cap to make the bearings shell fit;

install new bearing shells if fit on the

crankshaft is unsatisfactory.

14-95