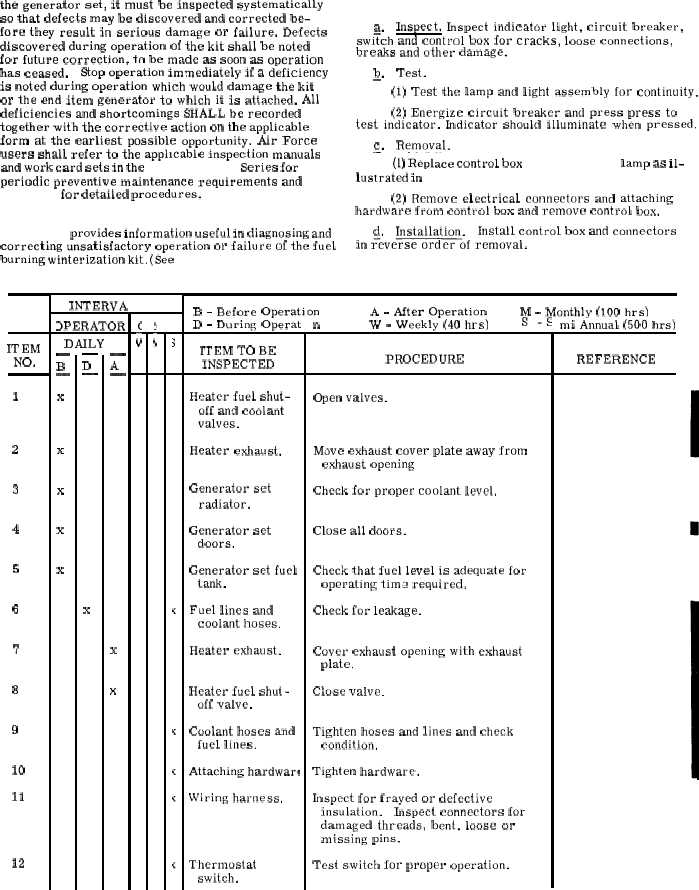

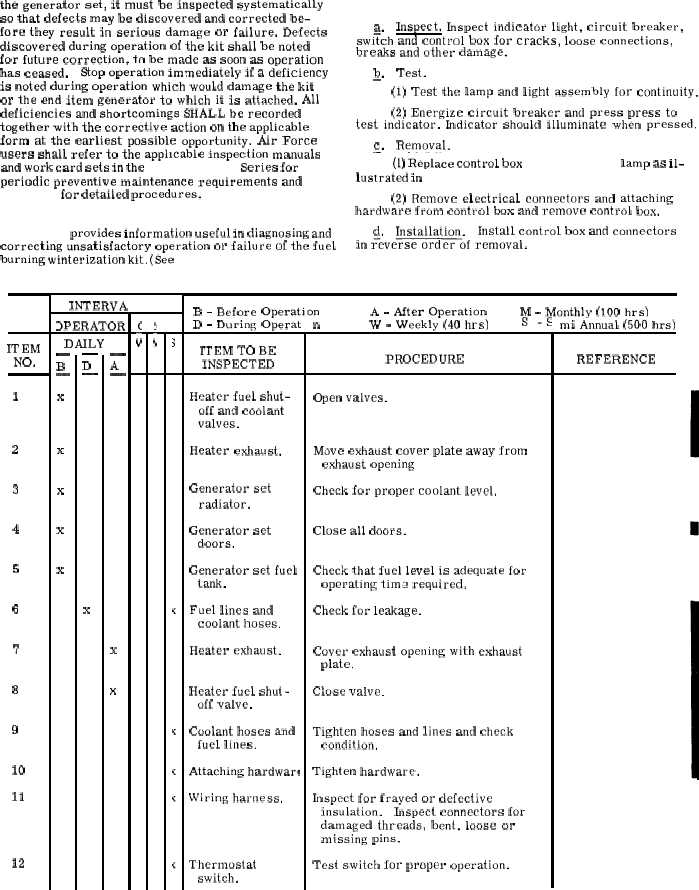

the generator set, it must be inspected systematically

4 - 8 . C o n t r o l B o x I n s p e c t i o n , T e s t i n g , a n d R e p l a c e m e n t .

so that defects may be discovered and corrected be-

fore they result in serious damage or failure. Defects

a.

Inspect. Inspect indicator light, circuit breaker,

discovered during operation of the kit shall be noted

swi~ch and control box for cracks, loose connections,

for future correction, to be made as soon as operation

breaks and other damage.

has ceased.

Stop operation immediately if a deficiency

is noted during operation which would damage the kit

or the end item generator to which it is attached. All

deficiencies and shortcomings SHALL be recorded

together with the corrective action on the applicable

form at the earliest possible opportunity. Air Force

users shall refer to the applicable inspection manuals

and work card sets in the T . O . 3 5 C 2 - 3 - Series for

periodic preventive maintenance requirements and

t a b l e 4 - 1 for detailed procedures.

4 - 7 .

T r o u b l e s h o o t i n g .

T a b l e

4 - 2 provides information useful in diagnosing and

correcting unsatisfactory operation or failure of the fuel

burning winterization kit. (See f i g u r e 1 - 2 2 , 1 - 1 5 o r 1 - 1 6 . )

ITEM

NO.

1

2

3

4

5

6

7

8

9

10

11

12

INTERVA

3PERATOR

DAILY

—

B

—

x

x

x

x

x

—

D

—

x

—

A

—

x

x

(

i

b.

Test.

—

(1) Test the lamp and light assembly for continuity.

(2) Energize circuit breaker and press press to

test indicator. Indicator should illuminate when pressed.

c.

Removal.

—

(1) R-eplace control box ( 1 4 , f i g . 4 - 1 ) lamp as il-

lustrated in f i g u r e 4 - 2 .

(2) Remove electrical connectors and attaching

hardware from control box and remove control box.

d.

Installation.

Install control box and connectors

in ~eve=d=of removal.

T a b l e

4 - 1 .

P r e v e n t i v e

M a i n t e n a n c e

C h e c k s

a n d

S e r v i c e s

:(

i

B - Before Operation

A - After Operation

M - Monthly (100 hrs)

D - During Operat

ITEM TO BE

INSPECTED

Heater fuel shut-

off and coolant

valves.

Heater exhaust.

Generator set

radiator.

Generator set

doors.

Generator set fuel

tank.

Fuel lines and

coolant hoses.

Heater exhaust.

Heater fuel shut-

off valve.

Coolant hoses and

fuel lines.

Attaching hardwart

Wiring harness.

Thermostat

switch.

n

W - Weekly (40 hrs)

S.-s

PROCEDURE

Open valves.

Move exhaust cover plate away from

exhaust opening

Check for proper coolant level,

Close all doors.

Check that fuel level is adequate for

operating time required.

Check for leakage.

Cover exhaust opening with exhaust

plate.

C:ose valve.

Tighten hoses and lines and check

condition.

Tighten hardware.

Inspect for frayed or defective

insulation.

Inspect connectors for

damaged threads, bent, loose or

missing pins.

Test switch for proper operation.

mi Annual (500 hrs)

REFERENCE

( f i g . 2 - 1 1 )

( p a r a

4 - 9 )

( p a r a 2 - 3 a n d 3 - 4 1

( f i g . 1 - 1 a n d 1 - 2 )

( p a r a

2 - 3 )

( p a r a

4 - 1 6 )

( p a r a

4 - 9 )

( f i g . 2 - 1 1 )

( p a r a

4 - 1 6 )

( p a r a

4 - 1 6 )

( p a r a

3 - 1 3 9 )

( p a r a

4 - 1 5 )

4

- 2

C h a n g e 1