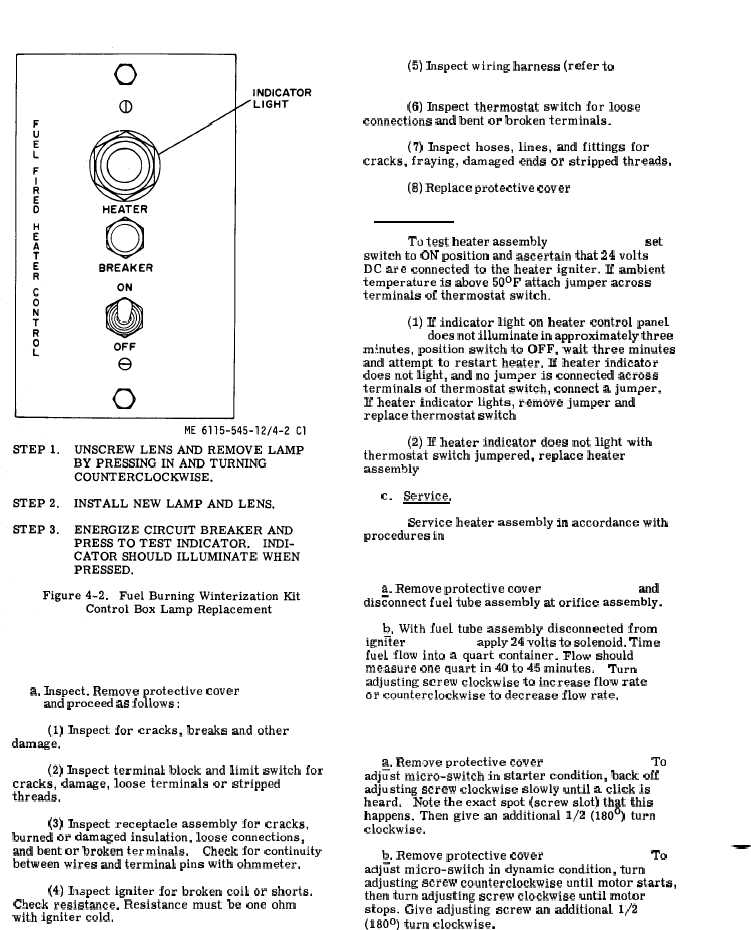

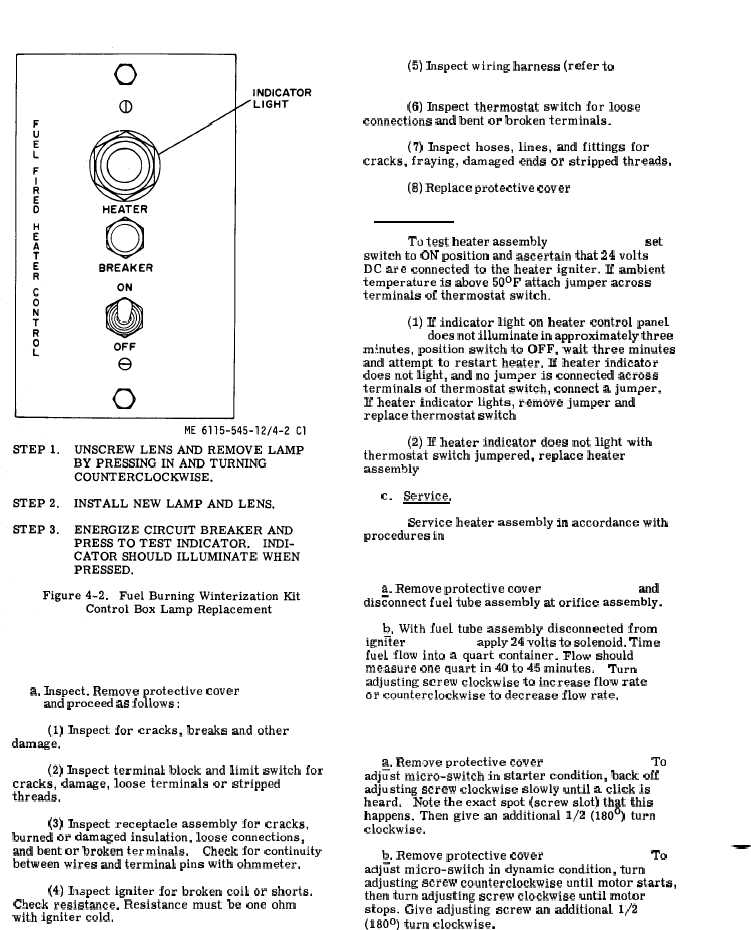

Figure 4-2.

b

. T

e

s

t

.

4 - 9 .

H e a t e r A s s e m b l y I n s p e c t , T e s t , S e r v i c e , a n d

A d j u s t .

a. Inspect. Remove protective cover

( 7 5 ,

f i g .

4 - 1 ) and proceed as follows:

(1) Inspect for cracks, breaks and other

damage.

(2) Inspect terminal block and limit switch for

cracks, damage, loose terminals or stripped

threads.

(3) Inspect receptacle assembly for cracks,

burned or damaged insulation, loose connections,

and bent or broken terminals.

Check for continuity

between wires and terminal pins with ohmmeter.

(4) Inspect igniter for broken coil or shorts.

Check resistance. Resistance must be one ohm

with igniter cold.

(5) Inspect wiring harness (refer to

p a r a -

g r a p h

3 - 1 3 9 ) .

(6) Inspect thermostat switch for loose

connections and bent or broken terminals.

(7) Inspect hoses, lines, and fittings for

cracks, fraying, damaged ends or stripped threads.

(8) Replace protective cover ( 7 5 , f i g . 4 - l ) .

To test heater assembly ( 6 1 , f i g . 4 - l ) , set

switch to ON position and ascertain that 24 volts

DC are connected to the heater igniter. If ambient

temperature is above 50°F attach jumper across

terminals of thermostat switch.

( p a r a

4 - 5 )

(1) If indicator light on heater control panel

( f i g . 4 - 2 ) does not illuminate in approximately three

minutes, position switch to OFF, wait three minutes

and attempt to restart heater. If heater indicator

does not light, and no jumper is connected across

terminals of thermostat switch, connect a jumper.

Jf heater indicator lights, remove jumper and

replace thermostat switch ( 3 9 , f i g . 4 - 1 ) .

(2) If heater indicator does not light with

thermostat switch jumpered, replace heater

assembly ( 6 1 , f i g . 4 - l ) .

c.

Service.

Service heater assembly in accordance with

procedures in t a b l e 4 - 1 .

4 - 1 0 .

F u e l

R e g u l a t o r

V a l v e

A d j u s t m e n t

( f i g .

4 - 3 ) .

a. Remove protective cover

( 7 5 ,

f i g .

4 - 1 ) and

disconnect fuel tube assembly at orifice assembly.

b. With fuel tube assembly disconnected from

ign~ter ( f i g . 4 - 3 ) apply 24 volts to solenoid. Time

fuel flow into a quart container. Flow should

measure one quart in 40 to 45 minutes.

Turn

adjusting screw clockwise to increase flow rate

or counterclockwise to decrease flow rate.

4 - 1 1 . F l a m e M i c r o - s w i t c h A d j u s t m e n t ( f i g . 4 - 4 ) .

a. Rem.we protective cover ( 7 5 , f i g . 4 - l ) . To

adj~st micro-switch in starter condition, back off

adjusting screw clockwise slowly until a click is

heard.

Note the exact spot (screw slot) that this

happens. Then give an additional 1/2 (180°) turn

clockwise.

b. Remove protective cover ( 7 5 , f i g . 4 - l ) . To

—

adjtist micro-switch in dynamic condition, turn

adjusting screw counterclockwise until motor starts,

then turn adjusting screw clockwise until motor

stops. Give adjusting screw an additional 1/2

(180°) turn clockwise.

4 - 8 C h a n g e 1