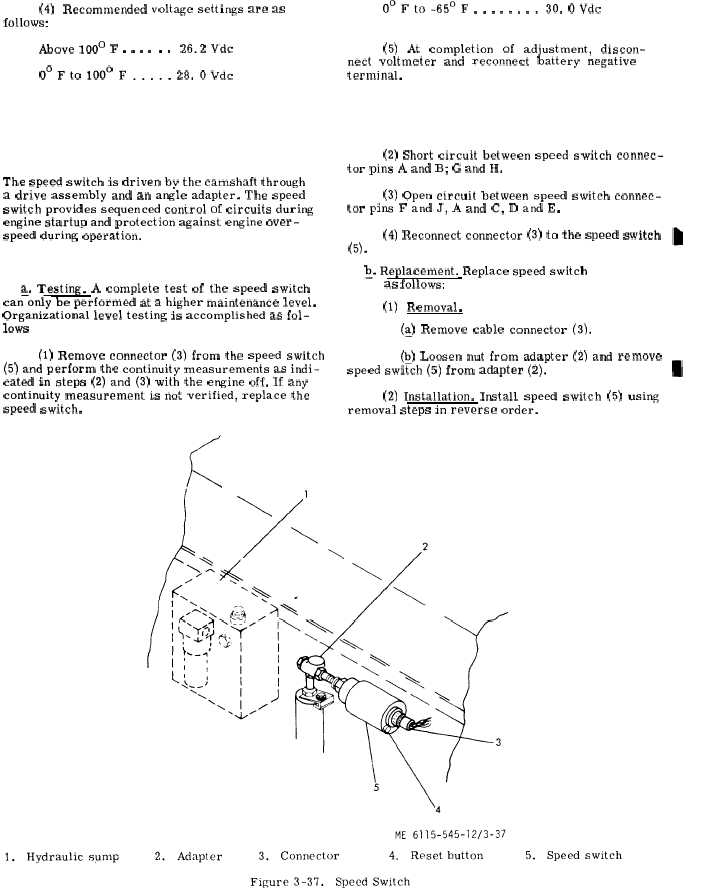

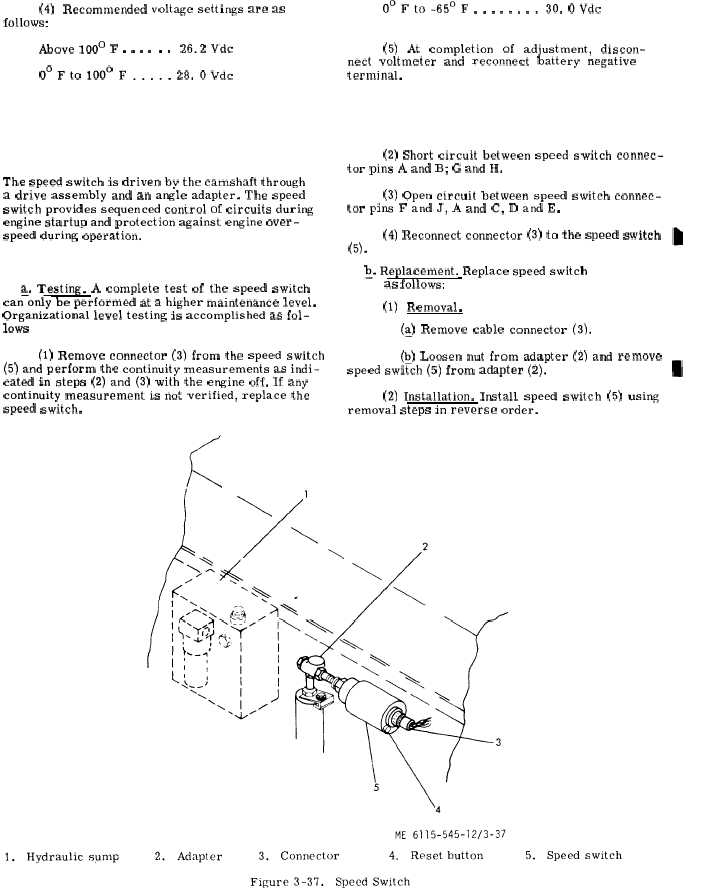

Figure 3-37.

(4)

follows:

Recommended

Above 100° F . . . .

voltage settings are as

. .

26.2 Vdc

O°Fto 1000 F..... 28. OVdc

S e c t i o n X X I X .

3 - 1 8 5 .

G e n e r a l .

The speed switch is driven by the camshaft through

a drive assembly and an angle adapter. The speed

switch provides sequenced control of circuits during

engine startup and protection against engine over-

speed during’ operation.

3 - 1 8 6 .

T e s t i n g

a n d

R e p l a c e m e n t .

a. Testing. A complete test of the speed switch

can–only be performed at a higher maintenance level.

Organizational level testing is accomplished as fol-

lows ( s e e f i g . 3 - 3 7 ) .

(1) Remove connector (3) from the speed switch

(5) and perform the continuity measurements as indi-

cated in steps (2) and (3) with the engine off. If any

continuity measurement is not verified, replace the

speed switch.

0°Fto-650F . . . . . . ..30. OVdc

(5)

At

completion

of

adjustment,

discon-

nect voltmeter and reconnect battery negative

terminal.

S P E E D

S W I T C H

(2) Short circuit between speed switch connec-

tor pins A and B; G and H.

(3) open circuit between speed switch connec-

tor pins F and J, A and C, D and E.

(4) Reconnect connector (3) to the speed switch

(5).

Q. Replacement.

Replace speed switch

( 5 ,

f i g .

3 - 3 7 ) as follows:

(1)

Removal.

(~) Remove cable connector (3).

(Q) Loosen nut from adapter (2) and remove

speed switch (5) from adapter (2).

(2) Installation. Install speed switch (5) using

removal steps in reverse order.

C h a n g e

3

3 - 9 1