TM 5-6115-465-34

TO35C2-3-446-2

NAVFAC P-8-625-34

TM06858B/06859D-34

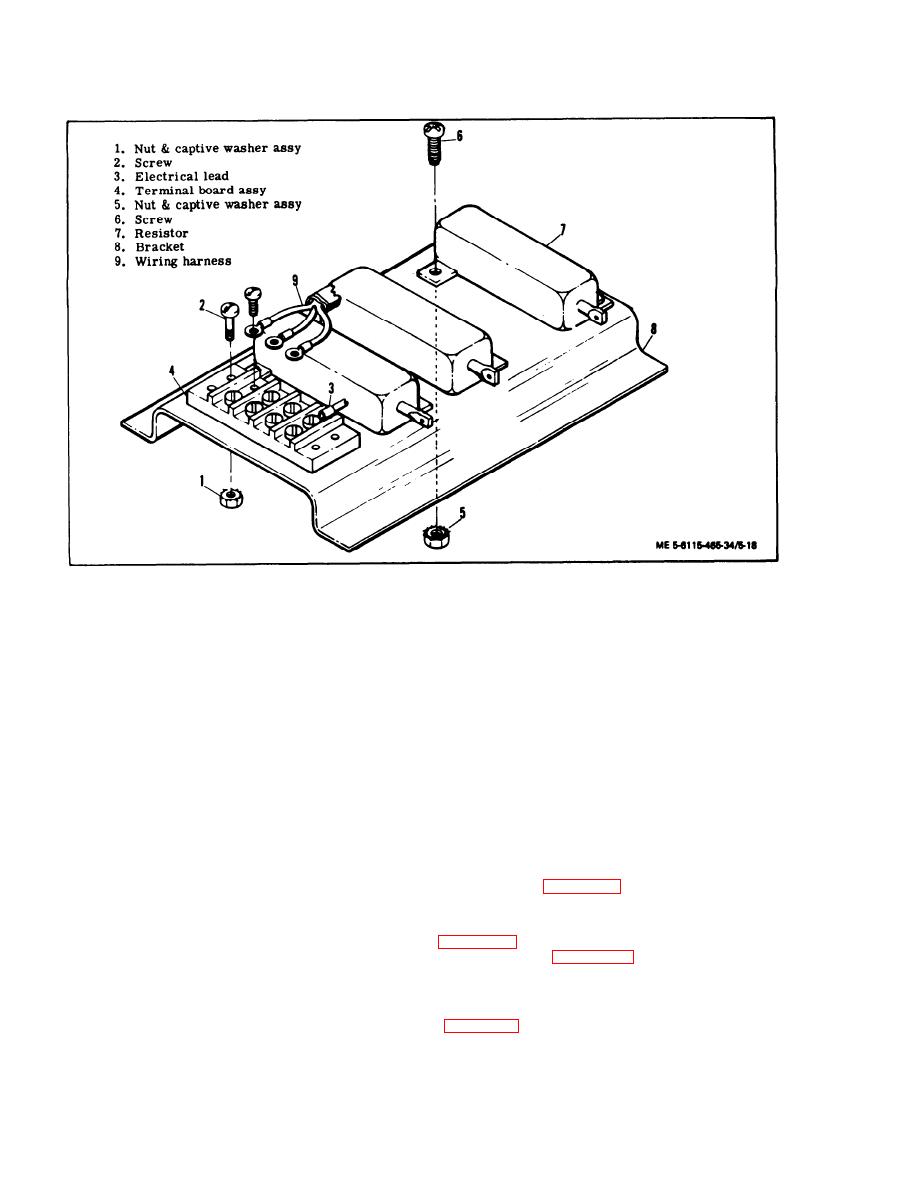

Tactical Relay Resistor Assembly, Exploded View

Figure 5-18.

(13) Using an ohmmeter, test potentiometer

(4) Inspect protective caps for cracks, ex-

as follows:

cessive wear, broken chain and other damage.

(a) Connect ohmmeter leads between cen-

(5) Inspect components of DC relay assembly

ter terminal and either outer terminal.

for cracks, burns, corrosion, and evidence of short-

ing or overheating.

(b) Slowly, at an even rate, rotate adjust-

ment from full counter clockwise to full clockwise

(6) Inspect instrument shunt for turns, corro-

position.

sion, and evidence of shorting.

(c) Ohmmeter indication shall change at an

(7) Inspect special current transformer for

even rate from O to 12 ohms.

corroded terminals and burns or other evidence of

shorting.

(d) Replace potentiometer if ohmmeter in-

dicates discontinuity at any point or if rate of change

(8) Inspect cranking relay K3 for cracked cas-

is erratic.

ing, corroded terminals, and evidence of shorting.

(14) Test wiring harness assembly wires for

(9) Inspect terminal boards for cracks, burns,

continuity using figure 5-20 as a guide.

corroded terminals and terminal jumpers and other

damage.

(15) If wiring, wiring harness has sustained

damage and requires repair or rebuild, refer to

(10) Inspect resistor for burns, corroded ter-

minals and other damage.

requirements and Appendix A for detailed soldering

and replacement procedures.

(11 ) Inspect chassis and cover for cracks,

warping, and illegible markings.

(16) Test dc relay assembly as follows:

(a) Apply 24 Vdc to terminals 6 and 15

(12) Check all threads for crossing, stripping,

and peening.

5-26