TM 5-6115-465-34

T035C2-3-446-2

NAVFAC P-8-625-34

TM06858B/06859D-34

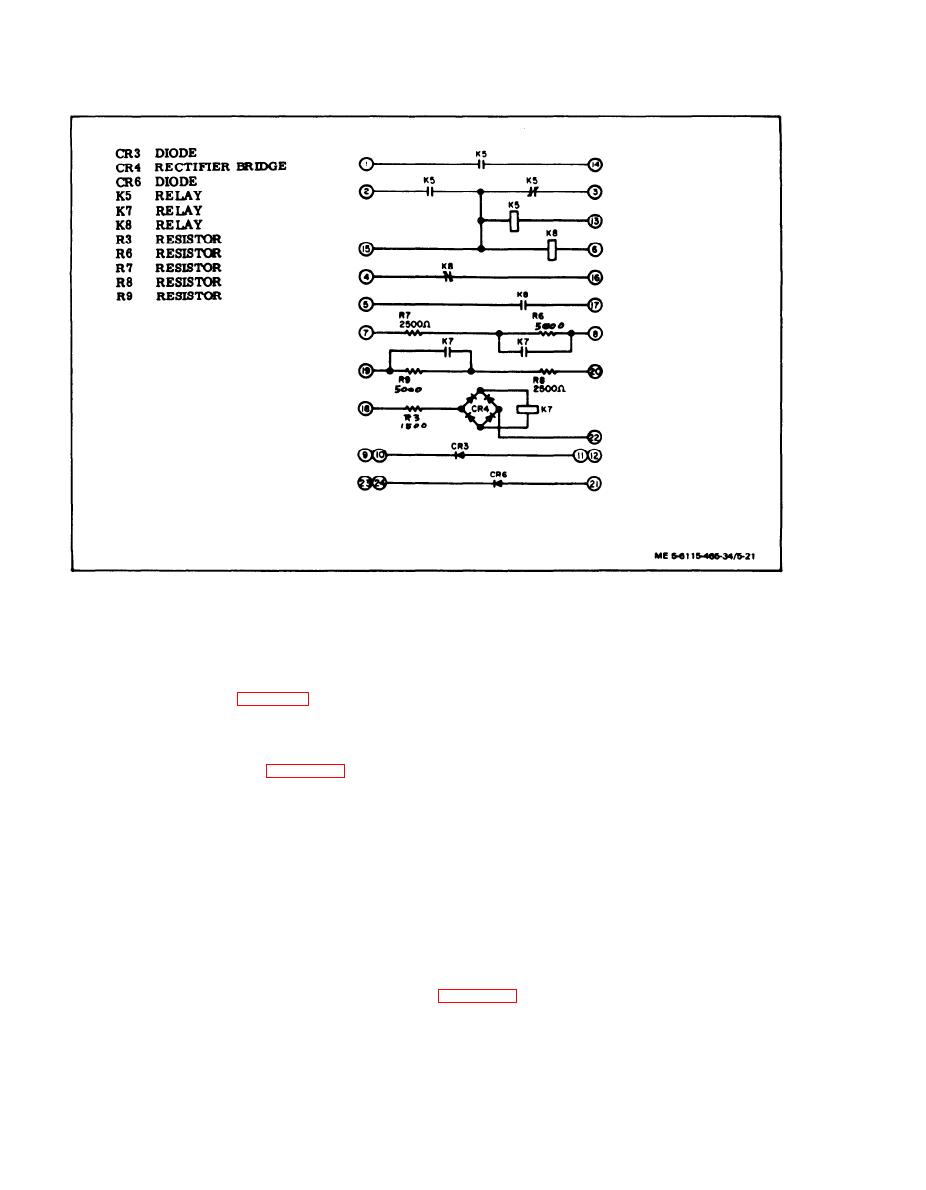

Figure 5-21.

DC Relay Assembly Schematic Diagram

(2) Visually inspect cover and chassis for

a.

Removal.

cracks, corrosion, warping, defective paint and

illegible markings.

(1) Disconnect electrical connectors to pre-

cise relay assembly.

(3) Inspect wiring harness for damaged wires

and connectors for bent or broken connector pins and

(2) Remove screws (1, figure 5-23) and lock-

burned areas indicating shorts.

washers (2) to remove precise relay assembly from

generator set.

(4) Inspect switch (50/60 Hz only) for cracked

casing, burro, corroded terminals and other damage.

b. Disassembly. Disassemble precise relay

assembly (items 3 through 33, figure 5-23) only as

(5) Inspect relays for cracked casing, corro-

required to clean, inspect, test, or replace parts.

ded terminals, and evidence of shorting or other

damage.

NOTE

(6) Inspect resistors and capacitors of elec-

tronic components assembly for insecure mounting

Switch and attaching hardware (items 21

and burns or other evidence of shorting.

through 24) are found only on the 50/60

Hz precise relay assembly.

(7) Inspect terminal board assembly for cracks,

c.

corroded terminals, damaged terminal jumpers and

Cleaning, Inspection, and Repair.

evidence of shorting.

(1) Clean precise relay assembly with filter-

(8) Test under voltage relay as follows:

ed compressed air and a soft bristle brush. If neces-

sary, caked deposits may be removed with a clean,

lint-free cloth moistened with an approved solvent.

(a) Install relay in test circuit shown in

Dry thoroughly after cleaning with solvent.

5-32