TM 5-6115-465-12

TO 35C2-3-446-1

NAVFAC P-8-625-12

TM 06858B/06859D-12

(1) Continuity between connector pins A and

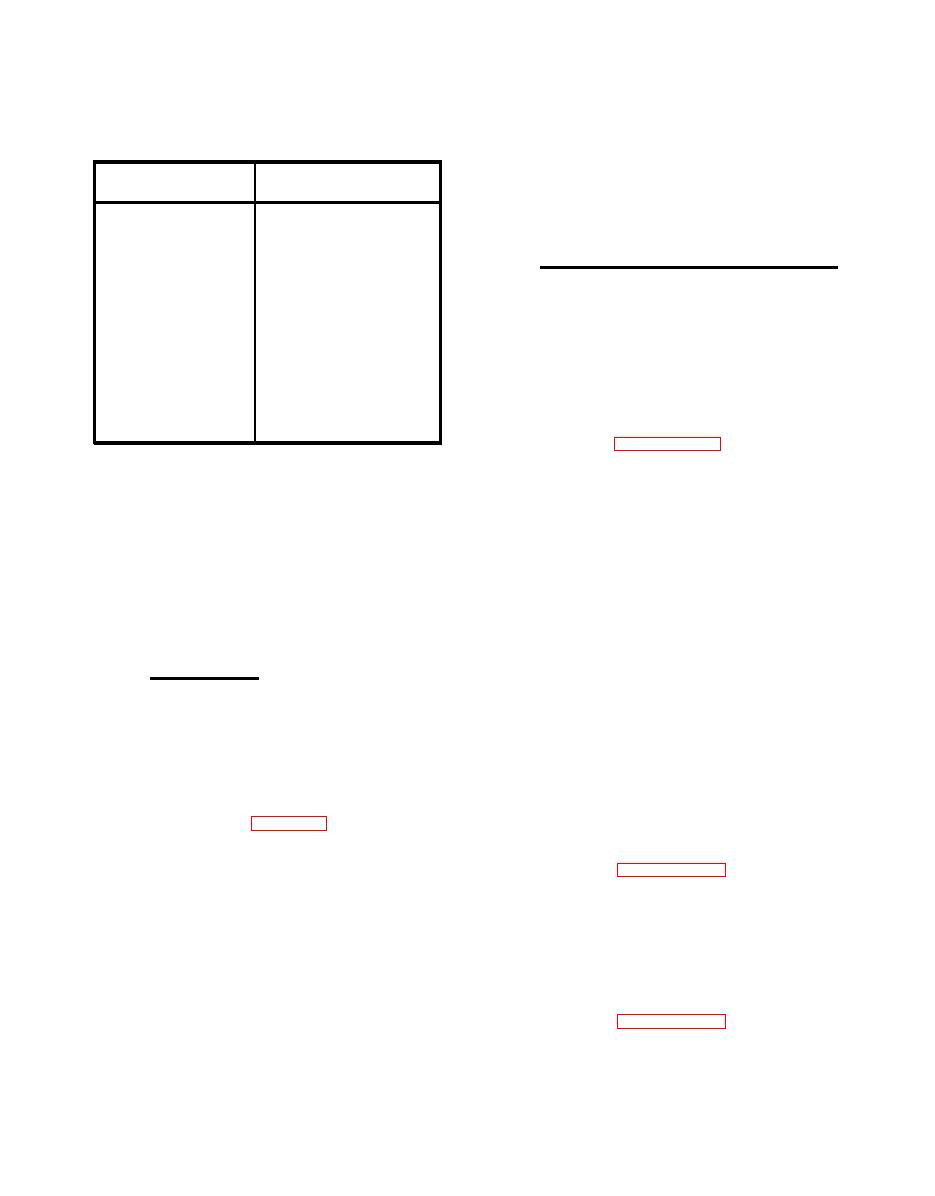

Alternator Voltages at Ambient

B and between pins G and H.

Temperature

(2) Discontinuity between pins A and C, be-

DC Voltage

Ambient

tween D and E and between F and J.

Minimum - Maximum

Temperature

d. Installation. Install speed switch in reverse

29.20-30.12

0 (-18)

order of removal procedures.

28.86-29.73

20 (-6.6)

COOLANT TEMPERATURE TRANSMITTER.

28.64-29.36

40 (4.5)

a . Removal.

28.32-28.98

60 (15.5)

NOTE

28.00-28.60

80 (26.6)

Test coolant temperature transmitter in

accordance with paragraph c. below

27.68-28.32

100 (38)

prior to removal. Coolant temperature

transmitter is located on the engine ther-

27.32-28.04

120 (49)

mostat housing.

(1) Refer to paragraph 3-31 and drain coolant

from the radiator.

NOTE

(2) Unscrew the wiring connector from the

temperature transmitter.

Rotating adjusting screw clockwise in-

creases voltage output. Rotating adjust-

(3) Unscrew the temperature transmitter

ing screw counterclockwise decreases

from the thermostat housing.

output .

b.

Cleaning and Inspection.

(11) If proper voltage cannot be obtained with

adjusting screw, replace alternator.

(1) Clean temperature transmitter with filter-

ed compressed air and a soft bristle brush or with a

d. Installation. Install battery charging alter-

clean lint-free cloth lightly moistened with an

nator in reverse order of removal procedures.

approved solvent.

SPEED SWITCH.

(2) Inspect temperature transmitter for

NOTE

cracked casing, corrosion and damaged threads and

connector.

Test speed switch in accordance with

paragraph c. below before removal.

c . Testing.

(1) Disconnect wiring harness connector from

a.

Removal.

coolant temperature transmitter.

(1) Remove wiring harness connector from

(2) Connect an ohmmeter or similar device

speed switch connector (figure 1-2).

between the connector and casing.

(2) Use 1-1/8 inch wrench to loosen and re-

move the speed switch.

(3) Refer to paragraph 2-10 and start the

engine.

b.

Cleaning and Inspection.

(4) Allow the engine to operate while observing

the ohmmeter.

(1) Clean speed switch with filtered compress-

ed air and a soft bristle brush or wipe with a clean,

(5) Resistance should increase to a reading of

lint-free cloth lightly moistened with an approved

680 to 745 ohms when the engine reaches normal

solvent.

operating temperature.

(2) Inspect speed switch for cracked casing,

(6) Refer to paragraph 2-11 and stop the

corrosion, bent or broken connector pins and

engine.

stripped or damaged threads.

c. Testing. Replace the speed switch, if any

of the following continuity or discontinuity y checks

(7) Replace coolant temperature transmitter if

are not verified.

resistance is not within specified limits.